Extrusion Know How

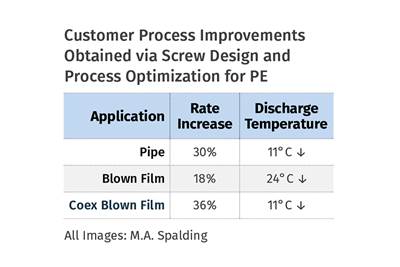

How Screw Design Can Boost Output of Single-Screw Extruders

Optimizing screw design for a lower discharge temperature has been shown to significantly increase output rate.

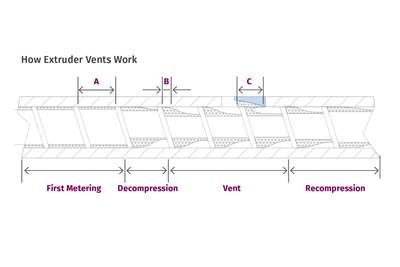

Read MoreTroubleshooting Vent Flow Problems in Single-Screw Extruders

Vent flow can be a costly problem and a housekeeping nuisance. Here is some advice on how to eliminate it.

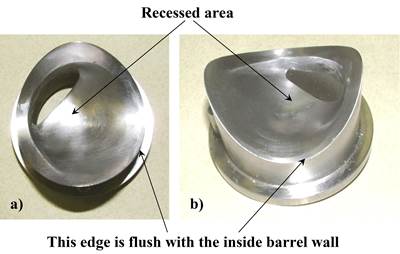

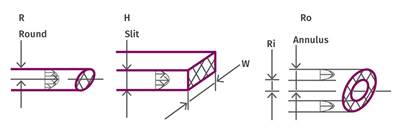

Read MoreThe Right Way to Design Vents in Single-Screw Extruders

Designing vents for single-screw extruders requires understanding of polymer flow in the screw channels. Some designs are more effective than others. Here are some guidelines.

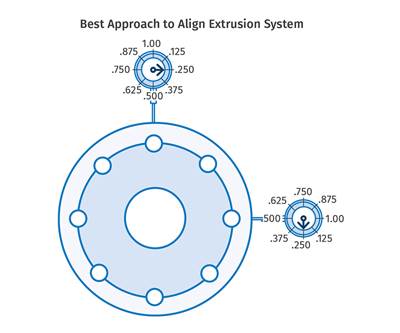

Read MoreExtruder Alignment: Important, but Only Half the Equation

The other half? Aligning and supporting downstream equipment. Here are best practices.

Read MoreWhy Compression Ratio is Important

Compression ratios have been pretty much standardized over the years, based on what has typically worked before. But there are quite a few variables that must be considered in order to get the optimum performance from your screw.

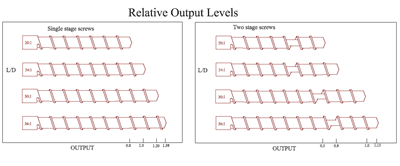

Read MoreHow Much L/D Do You Really Need?

Just like selecting the extruder size and drive combination, the L/D should be carefully evaluated.

Read MoreTake Proper Care in Feeding Your Extruder

Everything that happens in an extruder starts at the feed throat, so proper attention to that zone’s temperature pays off in quality and productivity.

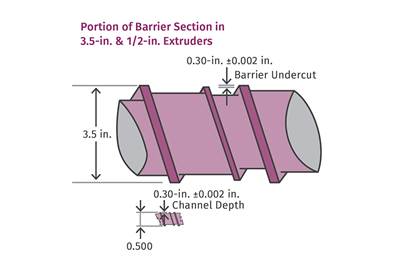

Read MoreSmaller Screws Impose Bigger Challenges

Very small extruder screws work just about like their larger cousins, but some critical differences make them harder to design and machine.

Read MoreHow to Estimate and Control Head Pressure

You rightfully worry about melt temperature, but don’t overlook head pressure, because the two are closely linked and will influence line performance.

Read MoreCooling the Feed Throat and Screw: How Much Water Do You Need?

It’s one of the biggest quandaries in extrusion, as there is little or nothing published to give operators some guidance. So let’s try to shed some light on this trial-and-error process.

Read More