Extrusion Know How

How Fillers Impact Extrusion Processing

Their addition can significantly change the processing properties of a polymer.

Read MoreBenchmark Your Extruders For Quicker Processing Fixes

Not recognizing output reductions and resolving them quickly can cost a lot of money. Benchmarking your machines will help.

Read MoreThe Truth About Barrel Heating

The main purposes of the heaters are to melt the polymer that remains in the barrel at cold startup, to assist in forming the initial melt, and to “trim” the barrel temperatures for specific purposes such as improving feed rate.

Read MoreWhere Does Shear Heating Occur? Here’s How to Find Out

One of the least understood yet most important concepts is viscous dissipation, which is the shearing or stretching of the polymer between the rotating screw and stationary barrel, causing heat to develop in the material.

Read MoreDead Screw Talking

There's a lot you can learn by conducting a post-mortum examination of your screw.

Read MoreScrew Surging, Part III: Unfilled Discharge Section

This type of surge happens most frequently with two-stage screws when the second stage has far more capacity than the first stage. It can also happen when a screw is limited in feeding or melting, causing a partially filled metering section.

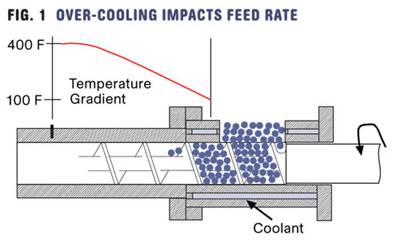

Read MoreOverfeeding Can Cause Surges, Too

Surging can be caused by feed restrictions, as covered in another column, and also by over-feeding or under-melting, discussed here.

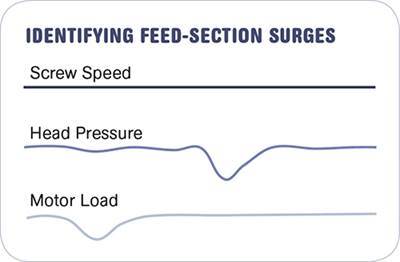

Read MoreSolving Feed-Related Surging

Understanding the causes of surging can help troubleshoot and correct it.

Read MoreExtrusion: A Roll Is a Roll Is a Roll?

Chill rolls may looks simple and shiny, but they play a critical part in cooling and polishing film and sheet and are not all the same.

Read More