Injection Know How

INJECTION MOLDING: Improving Barrel-Temperature Measurement and Control

Proper thermocouple placement and contact area are crucial, as is wire maintenance. But remember that barrel temperature and melt temperature are not the same

Read MoreINJECTION MOLDING: Get Control Over Barrel Zone Temperature Override

Poor temperature control results in an erratic melt stream and process. Here are some tips on how to get things under control.

Read MoreINJECTION MOLDING: Develop Guidelines—Not Strict Procedures— For a Robust Molding Process

‘Fool-proof’ dos and don’ts will prove foolhardy in a process with so many variables. You aren’t slinging burgers.

Read MoreINJECTION MOLDING: Gate-Seal Testing Done Right

Follow these 16 steps to perform the experiment and learn what is best for your part and process.

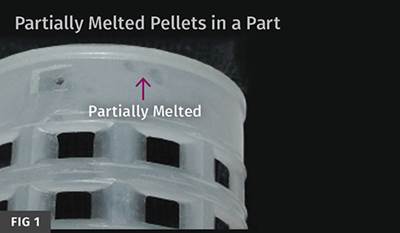

Read MoreINJECTION MOLDING: Why Pellet Size and Shape Are Important

Uniformity is needed to help ensure melt quality.

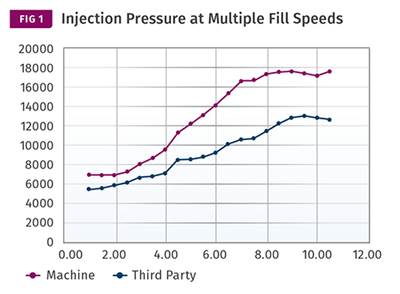

Read MoreUnderstanding Machine vs. Plastic Variables

Why setup sheets, DOEs, validations, etc. may not yield the results they should.

Read MoreINJECTION MOLDING: How to Specify an Injection Molding Machine

There are 51 things to consider when spec’ing a controller.

Read MoreINJECTION MOLDING: How to Specify an Injection Molding Machine

In part two of a three-part series, the focus is on the injection unit.

Read MoreINJECTION MOLDING: How to Specify an Injection Molding Machine

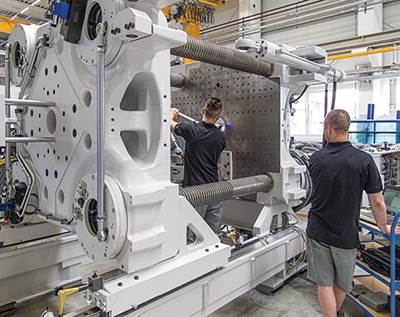

With the market percolating, more molders are looking at new presses. This series will discuss what you should consider before writing a check, beginning with the clamping unit.

Read MoreINJECTION MOLDING: Scientific Molding Gone Wrong

Sometimes molders get trained in Scientific Molding only to revert to their old way of doing things as soon problems pop up.

Read More