Injection Know How

How to Deal With Residual Stress in Molded Parts

Here are design, molding, and fixturing considerations to help you handle this unavoidable issue.

Read MoreHow to Manage Pressure Loss in Injection Molding

Achieving a process window wide enough to ensure consistent part quality depends on achieving sufficient pressure at end of fill.

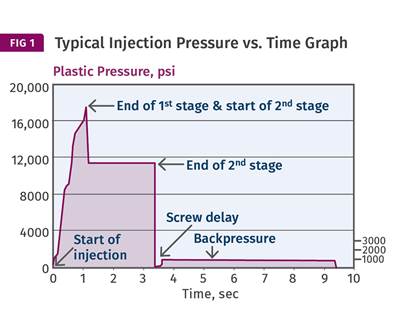

Read MoreHow to Quickly Verify Your Machine & Process Setpoints

For a quick check of your process setup, the injection-pressure-vs.-time graph is your best tool.

Read MoreThe 'Butterfly Effect' in Injection Molding—A Connected Process

In injection molding, a seemingly minor change in a setpoint can have a significant impact on part quality and process robustness and repeatability. That’s why Scientific Molding focuses on process outputs, not setpoints.

Read MoreMold-Clamping Details for Profit

Taking time to sweat the details of clamping is not much fun, but they do make a difference in a company’s bottom line.

Read MoreWhat’s With All the Static?

Static buildup on polymers can cause a variety of problems, some rather unpleasant. Yet there’s an inexpensive way to eliminate it, and we have data as proof.

Read MorePART 2: The Importance of Consistent Fill Time

To make identical parts, you need to keep fill time constant. In part one we covered the why. Here’s the how.

Read MorePart 1: The Importance of Consistent Fill Time

To make identical parts, you need to keep fill time constant. Here’s why.

Read MoreIdentifying and Correcting Splay

Splay adjustments can be a simple fix, or can require several hours of babysitting a press and head scratching. Learn to find the root cause.

Read MoreInjection Molding: Sliding vs. Locking Ring—Which Non-Return Valve Is Right for You?

The locking-ring style appears to dominate the market, as most believe it makes a make a better seal and leaks less. But is this really so?

Read More