Injection Know How

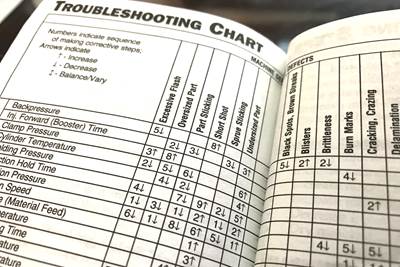

Apply the Power of a Troubleshooting Checklist to Your Process

Pocket guides provide processors an injection molding “crib sheet,” but in a process with thousands of interactions, applying if-this/then-that logic can’t always get you to a problem’s root cause.

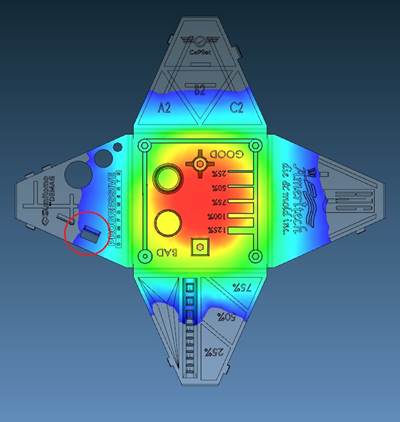

Read MoreThe Difference Between Knit and Meld Lines--and Why It Matters

In many part designs, flow fronts will inevitably be split, but how and where they come back together is hugely important to the molded part’s finished strength.

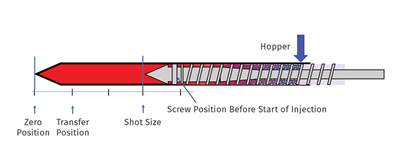

Read MoreConsider the Cushion When Seeking Shot-to-Shot Consistency

Creating and maintaining a consistent cushion is a key step in achieving shot-to-shot consistency. Learn what cushion is and how it affects part quality.

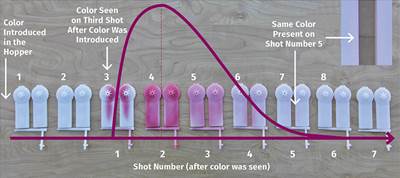

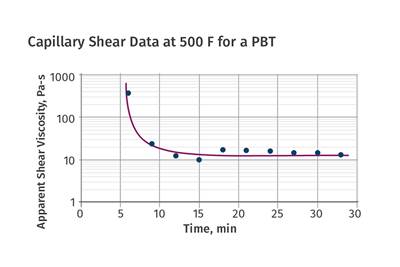

Read MoreThe Importance of Gauging Residence-Time Distribution—Part 2

Each molecule in the molded product can have a different residence time. This variance is reflected in the Residence-Time Distribution, which you can learn how to determine below.

Read MoreResidence Time and Residence-Time Distribution—Part 1 of 2

Failing to calculate and accurately account for residence time can compromise material integrity before it’s even injected.

Read MoreInjection Molding: Understand the Link Between Feed Throat Temperature & Bridging

Save time and money by properly controlling the feed-throat temperature. In some cases—but not all—it can help you solve a bridging problem.

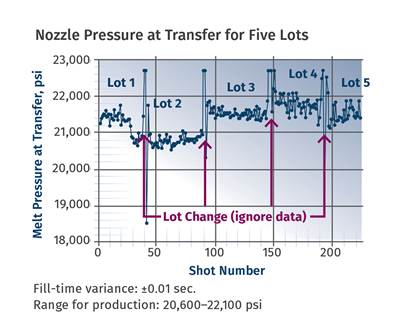

Read MoreHow to Know When Your Process is Ready to Make Acceptable Parts

Focus on six key metrics to help you determine when a process is lined out and stable enough to start production.

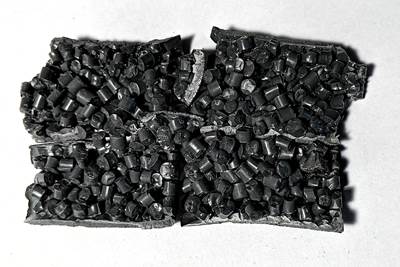

Read MoreBack to the (Re)Grind

Some amount of scrap—generated in startup, shutdown or defective parts—is inevitable. How can you reclaim regrind into new profitable parts?

Read MoreUse This Check List to Get Your Machine Properly Installed

Whether you bought a new machine or one that’s been refurbished, you need to prepare for installation so that it can be executed as seamlessly as feasible. Here some advice.

Read MoreFundamentals of Proper Press Shutdown

Press shutdown procedures have a significant impact on achieving smooth machine startups and restarts to improve uptime. Here’s a procedure you might want to deploy in your molding operation.

Read More