Injection Know How

The Cosmetic Process Window: Key to a No-Tweak, Robust Process

Establishing a process with the widest possible cosmetic window can help put your injection molding on cruise control.

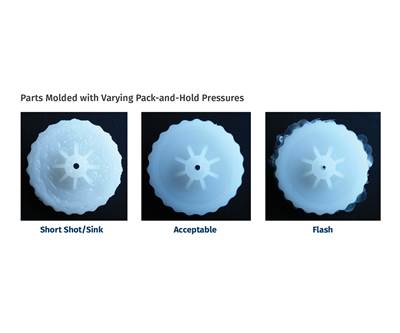

Read MoreDon’t Get Caught in the Flash-and-Shorts Chase

Injection molding’s most common defects can have inverse correlation, where correcting one causes the other, leading to the “chase.”

Read MoreFollow These Tips to Sanitize Machine Controller Screens & Buttons

Keeping your workers safe from the coronavirus makes it extremely important to institute a sanitizing procedure on all touch surfaces of the controller, screen and operating panel. I did some research and here’s what I found.

Read MoreIn Search of a Universal Setup Sheet

Duplicating a process from one injection machine to another is frustrating and time-consuming. Develop a mold-specific setup sheet that works in all kinds of presses by differentiating plastic parameters from machine parameters and duplicating those plastic conditions from machine to machine, electric or hydraulic.

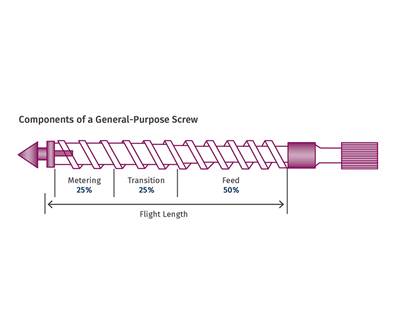

Read MoreRevisiting Shot Size vs. Barrel Capacity

We’ve covered this topic before, but it’s important enough to warrant another look..

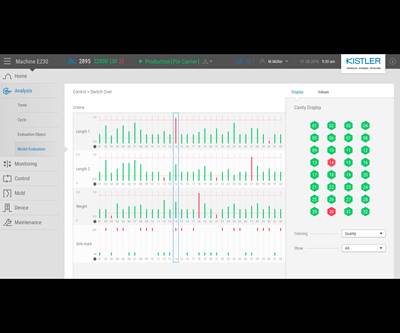

Read MoreHow Can Molders Achieve Effective Process Monitoring?

You have developed a proper process; now you need to monitor that process to ensure its stability through a run.

Read MoreChecking and Controlling Nozzle Body Temperature

Temperature control is critical from feedthroat to nozzle tip. Yet despite advances in machinery, this continues to be an issue for molders. Here’s what to do about it.

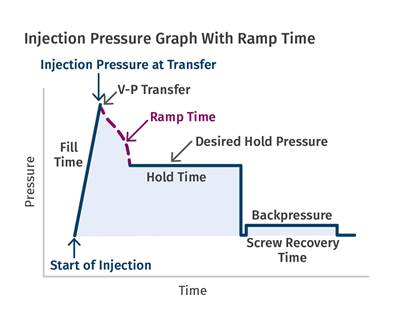

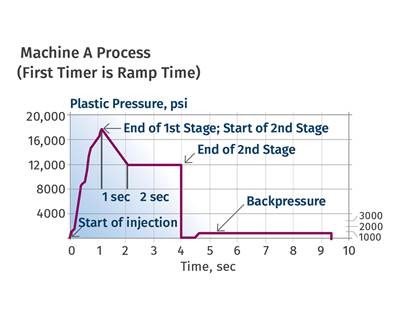

Read MoreV-to-P Ramp Time and Over-Travel

Many injection machines use ramp time to control the transition from injection pressure to hold pressure and reduce over-travel. Do you know how to set yours?

Read MoreGraphing Injection Pressure: What Should Pack & Hold Curves Show?

Are you sure your press is doing what you want? Visit your controller often to ensure your machines plot the pressure vs. time graph for all your processes. Here let’s focus on pack and hold.

Read MoreUnderstanding—and Using—Decompression to Your Advantage

Decompression—aka suckback—is a very important setting on an injection molding machine. On today’s machines, molders typically get the option to set decompression before and after screw rotation/recovery. Are they using this feature to their advantage?

Read More