Injection Know How

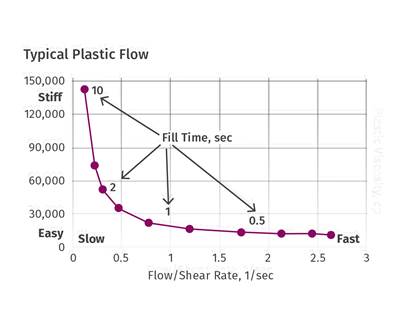

Injection Molding: DOEs Done Right

Doing DOEs for the sake of doing them wastes time and money. But they can provide vital information to determine which process variable is determining a critical part characteristic.

Read MoreInjection Molding: Put Out the Production Fire Once and for All

A deliberate approach to failure assessment, root-cause analysis, solution development, and continued monitoring is the only way to get off the treadmill of chasing the latest production problem.

Read MoreInjection Molding: Time for Another Look at Non-Return Valves

First and foremost, they must seal properly, and check valves with stepped angles or radiused seats perform the best.

Read MoreInjection Molding: Are You Using More Than 65% Of Your Barrel Capacity?

If you are, you are inviting Murphy—as in trouble—to the party.

Read MoreClamp Tonnage: More Is Better...Right?

Determining the correct tonnage provides a foundation that must be rock-solid to avoid flash and damage. But applying excessive force can create problems with the part, mold, and machine.

Read MoreHow to Duplicate a Process From Press to Press

To adopt the right approach you must distinguish between machine and plastic parameters.

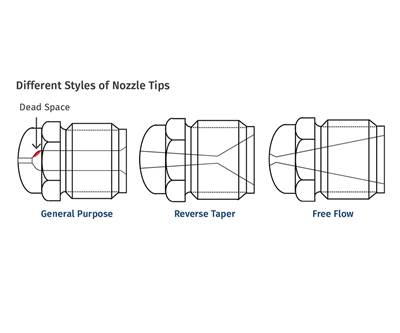

Read MoreHow to Pick, Remove, and Replace a Nozzle Tip

This small component can cause big problems. Here’s my procedure for picking and replacing yours.

Read More15 Things to Know About Servo-Driven Injection Machines

Drive technology for injection molding machines has been continuously evolving, and servo motors have become widely used in a variety of roles. Here’s what molders need to know about today’s servo drives in terms of cost, performance, maintenance, and training.

Read MorePlastics Technology’s Most Popular Know How Columns in 2016

Temperature, pressure and time ultimately dictate plastics processing so it鈥檚 not surprising that Know How columns from industry experts on these topics are consistently among the most popular on our site.

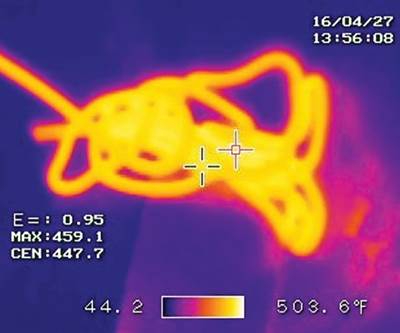

Read MoreUnraveling the Mysteries of Melt Temperature

Infrared technology can provide consistent and accurate readings of melt temperature. Here’s how to use it.

Read More