Injection Know How

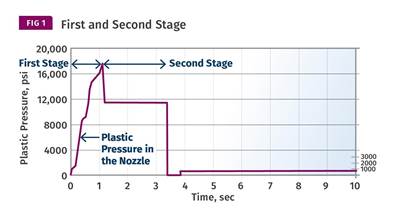

Injection Molding: Is There a ‘Most-Important’ Process Parameter?

A case can be made for multiple variables—fill balance, fill time, injection pressure, cavity pressure—as most important. But there is something else altogether that is essential to successful injection molding.

Read MoreInjection Molding: Fill Based on Volume, Not Weight

Most parts should be 90-99% full after first-stage—by volume not weight. Here’s why that’s important and how to make a first-stage-only part.

Read MoreInjection Molding: Safety First—Know the Compatibility of Different Resins

Certain materials don’t play well together when mixed. So it’s best not to. Here are some guidelines.

Read MoreInjection Molding: Process Documentation Is Crucial to Making ‘Identical’ Parts

Use a machine/mold setup sheet to document plastic parameters and use them on any acceptable machine into which the mold is placed.

Read MoreInjection Molding: A Practical Approach to Calculating Residence Time

Toss the formulas. The best way to determine residence time is to conduct a simple experiment.

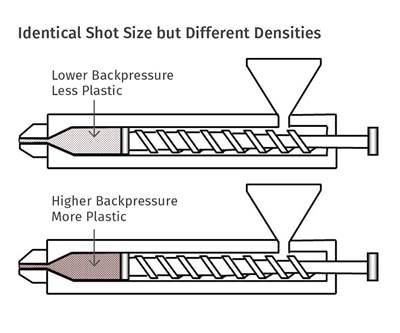

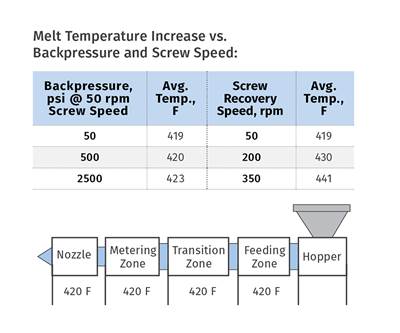

Read MoreInjection Molding: How Backpressure Adjustments Influence Shot Size

Raising backpressure results in increasing shot size, which can cause a host of other problems.

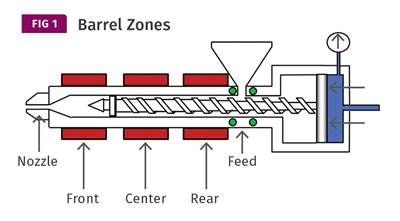

Read MoreInjection Molding: How to Set Barrel Zone Temps

Start by picking a target melt temperature, and double-check data sheets for the resin supplier’s recommendations. Now for the rest...

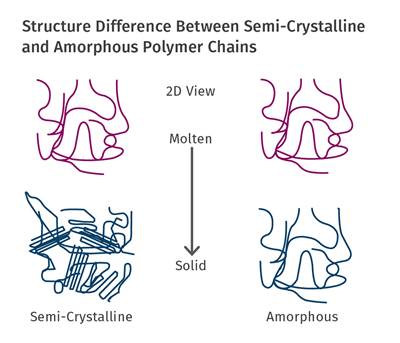

Read MoreInjection Molding: Melting Amorphous vs. Semi-Crystalline Plastics

Understanding the differences in how each melts is crucial to obtaining melt uniformity.

Read MoreInjection Molding: Nozzle Heaters & Thermocouples: A Case of Wiring Done Wrong

Incorrect placement of wires for these components frustrates molders and costs them money to boot.

Read MoreInjection Molding: No, Backpressure Does NOT Raise Melt Temperature

It’s a classic confusion between cause and effect. Melt temperature rises when screw speed is increased. Check out this data.

Read More