Injection Know How

What's Different About Molding Engineering Plastics

If you try to run them like commodity materials such as PP you'll have problems.

Read MoreTake a Scientific Approach to Troubleshooting

Taking a scientific approach minimizes the 'art' of molding, which is particularly helpful when troubleshooting

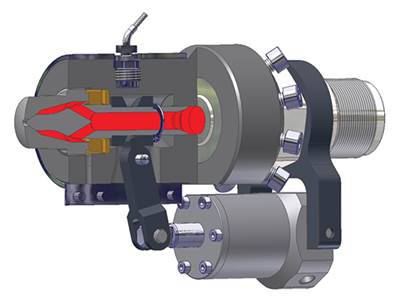

Read MoreScrew Decompress Before Screw Rotate

Thoughtfully determining when to start screw rotation to build the charge for the next shot can reduce the wear and tear on the screw tip, check valve, and screw motor.

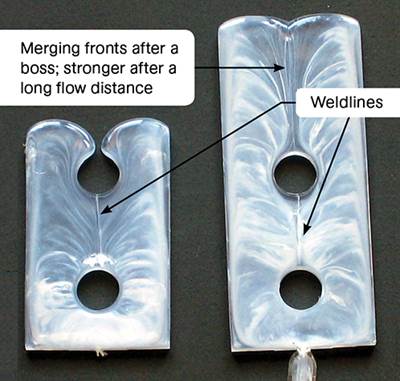

Read MoreCoping with Weak Weld Lines

Weld lines cause significant reject rates and are a common problem that all molders face.

Read MoreMinimize Screw Recovery & Cycle Times

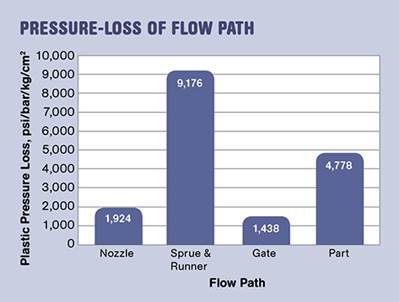

There are hundreds of details you must identify and control to run a successful molding plant. One that is almost always at the top of the list is optimizing cycle time. Shorter cycles that make acceptable parts improve profits.

Read MoreHow to Specify A Resin Dryer

To dry your polymer correctly you need a dryer that is properly designed and working properly. Here are my suggested specifications, for a two-, three- or four-bed desiccant dryer, the most common types used.

Read MoreTop 10 Reasons Why Molders Fail At Implementing ‘Scientific Molding

What is Scientific Molding? And why do molders seem to have such a difficult time embracing its concepts? Here are some thoughts on the matter.

Read MoreGet the Most From Your Tooling

The history and culture of the molding industry has been to pull out every trick possible to work around design, resin, tooling, processing, and testing issues once the mold arrives. It is time to rewrite history.

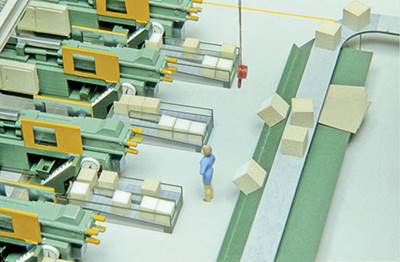

Read MoreEstablish a True ‘24/7’ Production Process

New or existing mold trials need to produce a production-worthy process that will run 24/7.

Read More