Injection Know How

Injection Molding: Why & How to Do Gate-Seal Experiments

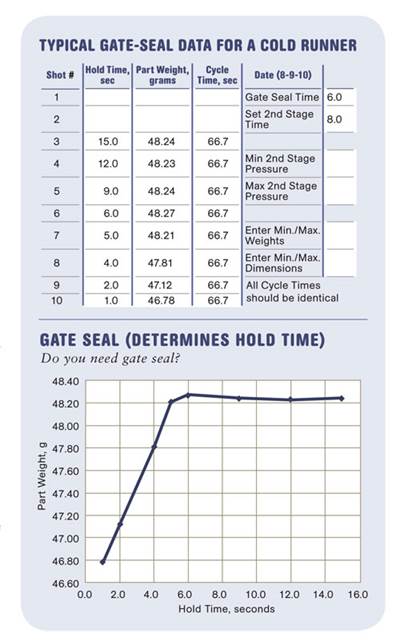

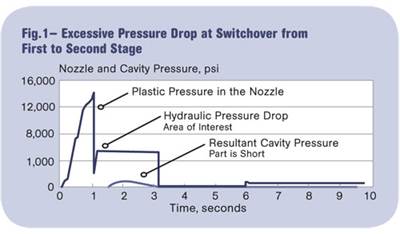

Part of optimizing any molding process is determining the second-stage injection, or pack and hold, parameters.

Read MoreInjection Molding: Answers to Bozzelli's Drying Quiz

Three questions about drying plastics that everyone should know how to answer.

Read MoreInjection Molding: You Must Dry Hygroscopic Resins

The reason you dry certain plastics is to get the moisture out. But why does the moisture have to be taken out before processing?

Read MoreInjection Molding: Time Now for a Safety Review

For months many of us have been consumed with the Gulf oil pipeline blowout.

Read MoreInjection Molding: The Basics of Machine Evaluation, Part III

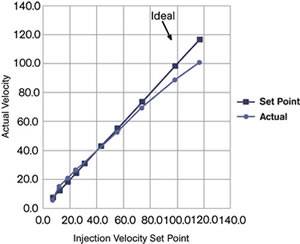

In the last two issues, we started defining some basic tests to ensure your injection molding machine is working properly.

Read MoreThe Basics of Machine Evaluation, Part II

Last month we started defining some basic tests to ensure your injection molding machine is working properly.

Read MoreKnow the Basics of Machine Evaluation, Part I

Ever wonder how many shots are made each day via injection molding?

Read MoreHow to Make the Transition to Electric Presses

Electric injection machines are becoming more and more prevalent, and as they hit the shop floor, you are responsible for making them produce parts with dimensions, appearance, and performance to client specifications.

Read MoreDon't Neglect Cooling... There's Money to Be Made

For most injection molding jobs, cooling is 95% of the cycle time.

Read MoreBalanced Filling Is Critical for Holding Molding Tolerances

Processors face a multitude of challenges whenever they approach an injection molding machine.

Read More