Injection Know How

Calculate Shot Size Vs. Barrel Capacity

It may seem like a dull topic, but it will overcome the emotional experience that follows when you put a new mold into a machine and you find out there is not enough barrel capacity to make a full shot.

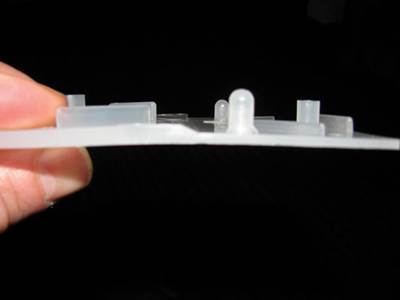

Read MoreShort Shots Redux

Deliberately making a short shot permits you to do a scientific molding viscosity curve. It will also prevent you from damaging the mold by overpacking if you set shot size incorrectly.

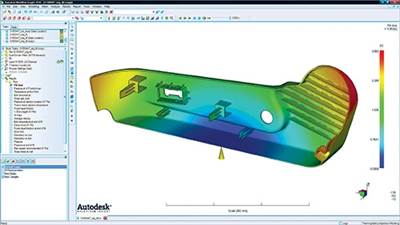

Read MoreMold Filling Simulation: What, When, Why, How

Mold-filling analysis is the right direction to go, but if you want to arrive at your destination—good parts and an efficient process—you’ll need to pay attention to all the details and select an experienced professional to do the analysis.

Read MoreScrews and Pellets: One Size Does Not Fit All

Screw design, pellet type/size and material behavior are all critical issues to consider to deliver uniform melt to the mold.

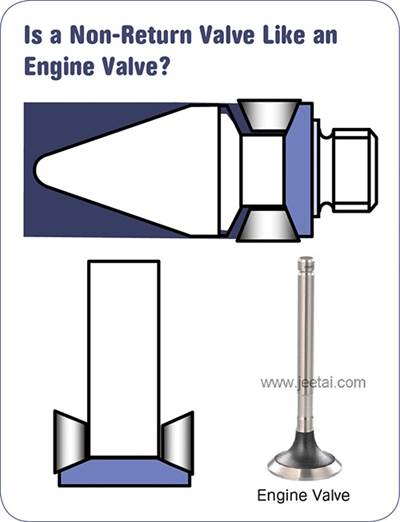

Read MoreWhy Non-Return Valves Leak

We all recognize that the non-return valve is a problem. The question is where is the research to figure out how to correct this so we have a better shot at making more consistent parts

Read MorePay Attention to Your Nozzle Body & Tip

These are overlooked components that can cost you thousands.

Read MoreInjection Molding: How to Set Second-Stage (Pack & Hold) Pressure

Most molders work with two parameters for establishing second-stage pressure. But within Scientific Molding there are actually four.

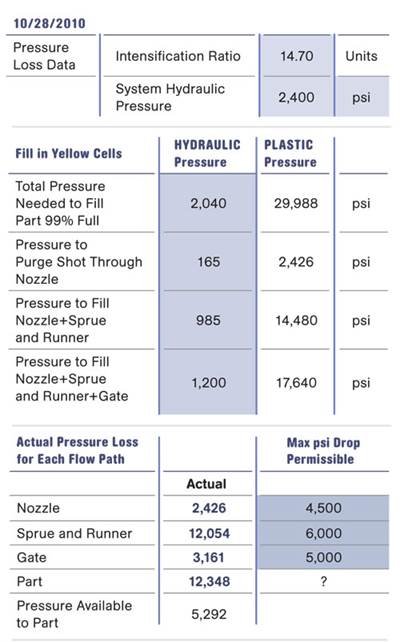

Read MoreInjection Molding: Understanding Pressure Loss In Injection Molding

One of the more prominent trends in processing is the need for higher plastic pressures to mold parts.

Read MoreInjection Molding: Processors: Teach Part Designers The Golden Rule

Make sure the designers you work with understand that there are limits to what processing can do.

Read More