Injection Know How

Nozzle Leaks: Why They Occur, How to Detect & Fix Them

Nozzle leaks are a serious problem in injection molding. Here are some causes and remedies.

Read MoreShould You Profile Injection Velocity?

If you can get by with one velocity, use only one, because fill time is easier to reproduce, and it is easier to set up the process.

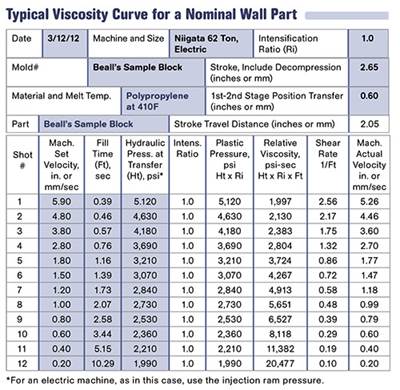

Read MoreUnderstanding Polymer Flow: Interpreting the Viscosity Curve

Take the time to do the viscosity curve on new molds. You will learn more in that hour than many learn in years about the process for this tool.

Read MoreGetting Good Data from DOE

How do you know what process variables control a part鈥檚 dimensions or other properties? A properly conducted DOE is the answer鈥攂ut incorrect procedure will yield useless data.

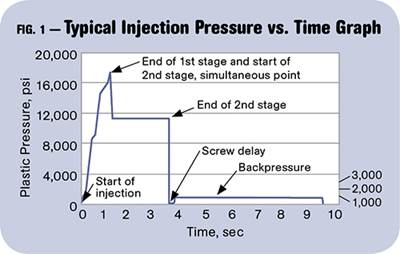

Read MoreImprove Profits by Graphing Injection Pressure

Graphing is a powerful aid in optimizing the process and troubleshooting both process and machine issues.

Read MoreWhat to Calibrate on Your Press

There are different approaches to meeting the goal of making parts identically. At the heart of all them is the process or the machine setup sheet. My bet would be you cannot find two that are identical.

Read MoreWhy Multi-Cavity Molds Fill Unevenly

Balanced filling is critical for making identical parts, achieving high CPKs, holding tight tolerances, and getting “good” data from design of experiments.

Read MoreWhat Percentage of Barrel Capacity Should Your Shot Size Be?

The answer combines both experience and science, and it may be one of those molding details that gets overlooked but could be stealing a chunk of your profits.

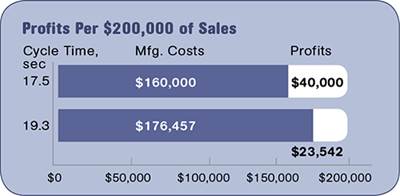

Read MorePlasticating Rates: Your Profits Are at Stake

To get the best cycle time you need the right machine, and few molders take the time to specify this critical component of the process.

Read More