processing tips

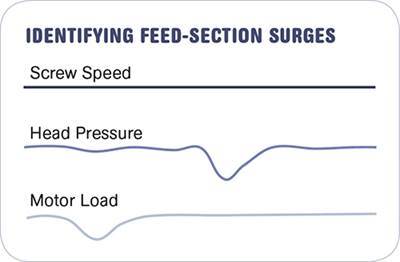

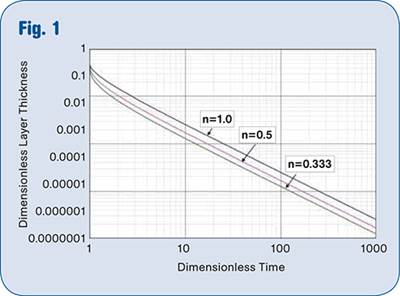

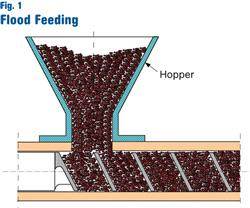

Solving Feed-Related Surging

Understanding the causes of surging can help troubleshoot and correct it.

Read MoreWhat to Look for in a Modular, Reconfigurable Conveyor System

As conveyors have become a necessity on the plant floor, conveyor manufacturers have attempted to respond to end-users’ needs for flexibility by creating truly modular, reconfigurable systems.

Read MoreTips and Techniques: How to Mold & Extrude Using Chemical Foaming Agents

Here are some tips and techniques for extruders and injection molders to refer to when using CFAs.

Read MoreExtrusion: A Roll Is a Roll Is a Roll?

Chill rolls may looks simple and shiny, but they play a critical part in cooling and polishing film and sheet and are not all the same.

Read MoreInjection Molding: How to Set Second-Stage (Pack & Hold) Pressure

Most molders work with two parameters for establishing second-stage pressure. But within Scientific Molding there are actually four.

Read MoreTips and Techniques: Boosting Extrusion Productivity - Part III of III: Trim Your Material & Energy Costs

Material cost is the largest cost factor in most extruded commodity products, so processors should be motivated to reduce these expenses.

Read MoreHow to Set Up & Maintain An Efficient Resin Handling System

In today's world, having a reliable resin-handling and conveying system is as important as having reliable electrical power.

Read MoreExtrusion: Start Up and Shut Down Properly

A key goal during startup and shutdown of the extruder is to prevent degradation of the polymer left in the extruder and downstream components such as screen changers, adapters, and dies.

Read MoreBoosting Extrusion Productivity-Part II of III: Optimize Product Changeover & Purging

Extrusion processors typically run a number of different products and resins.

Read MoreHow to Get Peak Performance & Efficiency Out of Your Extrusion Line, Part I

A lot of things must be in place to achieve what I like to call efficient extrusion.

Read More