processing tips

Central or Portable? ‘Off-the-Floor’ Central Chillers Cost Less, Provide Processing Gains

In deciding whether to use portable or central chillers, there are a variety of variables to consider. Here are the key issues.

Read MoreCentral or Portable? Flexibility Favors ‘Discrete’ Chillers

Why might discrete chillers be a solution in your plant? In a word: Flexibility. Here is the lowdown.

Read MoreHow to Keep Your Conveyor Running Smoothly

Low-profile conveyors are ubiquitous in industry, typically used in 24/7 applications in packaging, assembly, labeling, inspection, and sorting. Here's how to keep them up and running.

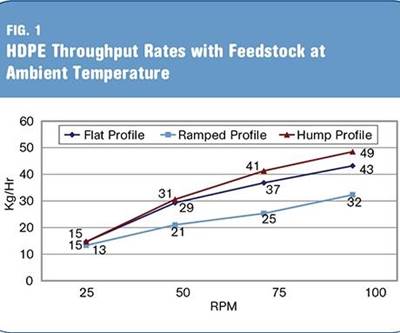

Read MoreBenchmark Your Extruders For Quicker Processing Fixes

Not recognizing output reductions and resolving them quickly can cost a lot of money. Benchmarking your machines will help.

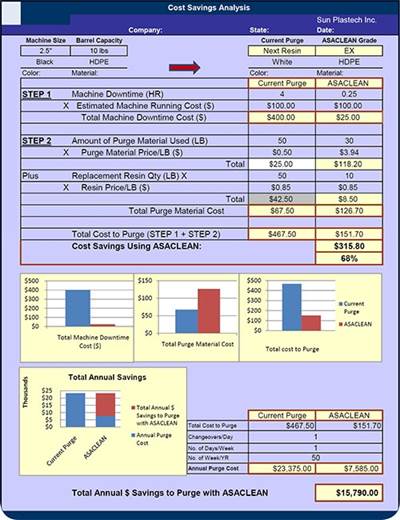

Read MoreHow to Use Commercial Purging Compounds in Extrusion

CPCs are considered most often for injection molding. However, they also can provide the same benefits to extrusion processors.

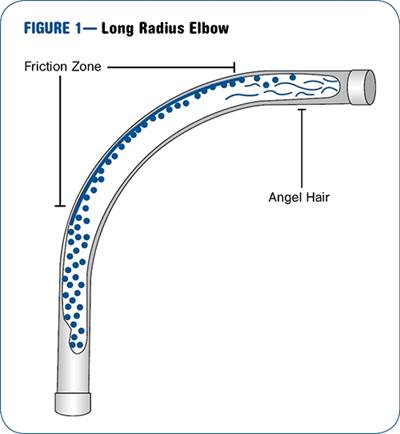

Read MoreAvoid Those Devilish ‘Angel Hairs’

Angel hairs wreak havoc on plastics processing: clogging filters, plugging conveying lines, causing feed problems at the blender, and jamming up machine throats. Here's how to prevent their formation.

Read MoreShort Shots Redux

Deliberately making a short shot permits you to do a scientific molding viscosity curve. It will also prevent you from damaging the mold by overpacking if you set shot size incorrectly.

Read MoreThe Truth About Barrel Heating

The main purposes of the heaters are to melt the polymer that remains in the barrel at cold startup, to assist in forming the initial melt, and to “trim” the barrel temperatures for specific purposes such as improving feed rate.

Read MoreBoost Performance, Speed, Economy with Servo-Controlled Welding

Ultrasonic welding is one of the most widely used processes for bonding polymers, valued for its speed, flexibility, and low cost.

Read MoreWhy—and How—to Baseline Your Extruder

If you don’t baseline your extruder, then how are you going to set realistic expectations for its performance? Here's how to get going.

Read More