processing tips

Which Winder’s for You?

It's time to apply more science to the process of selecting the right kind of winder for your operation.

Read MoreWhy I Still Like Analog Meters

They may not look as slick as their digital cousins, but I find them more helpful in identifying and troubleshooting extrusion problems.

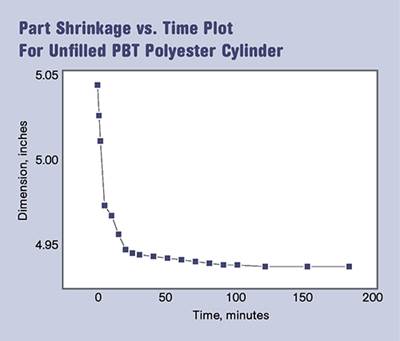

Read MoreDimensional Stability After Molding: Part 1

The degree to which molded parts shrink as they cool is largely dependent upon the composition of the material being processed.

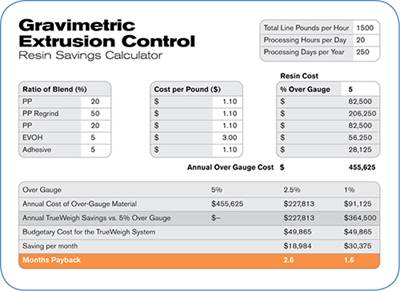

Read MoreHow Gravimetric Control Systems Pay Off in Blow Molding

Gravimetric control systems offer blow molders improvements in processing efficiencies above and beyond their ability to regulate resin usage.

Read MoreWorking with Color Concentrates

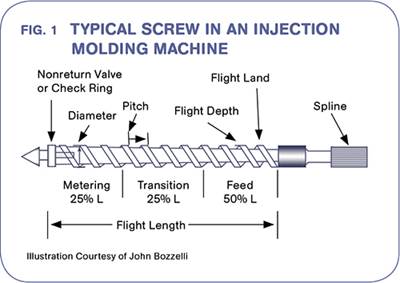

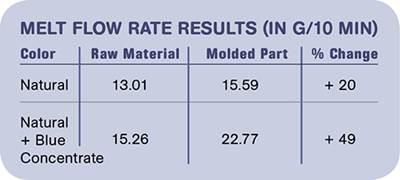

Industry needs more development of enhanced-mixing screws.

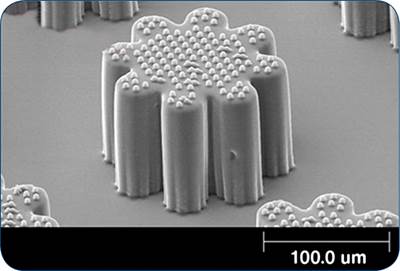

Read MoreSecrets of Success in Micro Molding

Medical-device, electronics, and biopharmaceutical manufacturers need new micro-molded products to create tinier, less invasive, and/or space-saving micro devices.

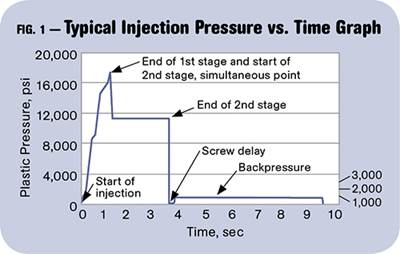

Read MoreImprove Profits by Graphing Injection Pressure

Graphing is a powerful aid in optimizing the process and troubleshooting both process and machine issues.

Read MoreWorking with Color Concentrates

Perhaps the greatest difficulty involving the use of color concentrates is specifying them appropriately for the material to which they are being added.

Read MoreFive Cases Where Microcellular Foaming Paid Off

The MuCell process for producing microcellular injection molded parts is used and accepted globally as a technology option for providing a more dimensionally stable part through a reduction in residual stress, along with increased productivity versus solid injection molded parts.

Read MoreGet Better at Multi-Material Molding

Since each multi-material application is unique, there’s no standard best method for success. Each molding solution must be tailored to meet the needs of the final product.

Read More