processing tips

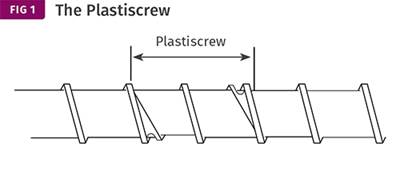

EXTRUSION: Why Barrier Screws & Rigid PVC Don’t Always Mix

RPVC’s somewhat unusual melting mechanism makes it unsuited to traditional barrier type designs.

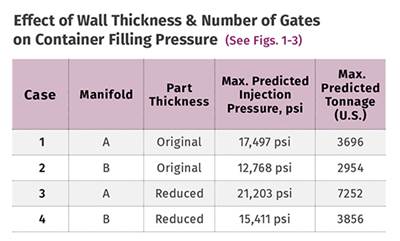

Read MoreINJECTION MOLDING: The Importance of Nominal Wall For Lightweighting Molded Parts

Establishing a nominal wall is one of the most important decisions an engineer makes when designing parts. Understanding how design changes will impact the manufacturing process is critical to ensure the part performs as expected.

Read MoreMATERIALS: Don’t Guess Your Way Through Root Cause Analysis

More than 50 different polymer test techniques can be used to find root causes of problems. Of these, five or six are fairly common. Use them to take the guesswork out of why a product failed.

Read MoreHow to Avoid Problems When Using Commercial Purging Compounds

The best approach is to implement and standardize a three-step program to ensure you are purging in the best and most cost-effective manner possible.

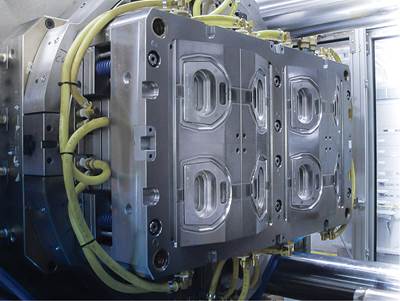

Read MoreMold-Heating/Cooling Technology Keeps Cosmetic Parts Looking ‘Hot’

New rapid mold-temperature control technology allows molder to eliminate cosmetic defects like knit lines or sink marks in parts that require a glossy finish or feature texturing.

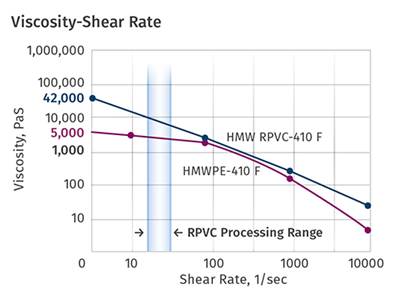

Read MoreEXTRUSION: Processing Rigid PVC? Know Your Rheology

Before choosing and sizing extruders for running rigid vinyl, it is wise to bone up on the viscosity behavior of the material.

Read MoreMATERIALS: Performance in Polyethylene: Density Matters: Part II

Remembering the case of the failed gas tanks.

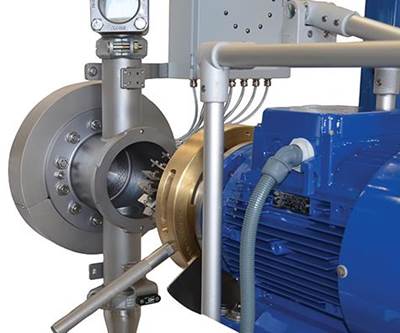

Read MoreSolving Common Problems in Underwater Pelletizing

Pellet quality and consistency are critical to any compounding operation. But in underwater pelletizing, a variety of issues can stand in the way. Here’s how to fix them.

Read MoreResin Conveying: No More ‘Spaghetti Bowl’

You now have technology choices to avoid the maze of conveying tubes that form a ‘spaghetti bowl’ or ‘rat’s nest’ in a central materials-handling system. Here’s how they stack up.

Read MoreTOOLING: Balancing the Heat Budget In Injection Molds

Basic formulas for how much heat you must pull out of the mold to achieve a set cycle time

Read More