processing tips

Granulate or Shred: Which Makes Sense for You?

That is the size-reduction question confronting many processors today. Look here for some guidance.

Read MoreUnderstanding Your Options In Multi-Axis Robots For Injection Molding

With so many choices available today, it’s important for molders to understand the pros and cons of Cartesian vs. articulated-arm robots and how their capabilities overlap more than ever before.

Read MoreMATERIALS: Melt Flow Rate Testing—Part 10

Two areas where the melt flow rate test it is not useful are related to processing.

Read MoreA Better Way to Balance Die Flow

Use temperature adjustments before making any mechanical tweaks.

Read MoreScrew Speed Versus Recovery Time

Many molders don't take screw-rotation speed into account when developing a process for a new mold. Here's why they should.

Read MoreCompounding PLA on Twin-Screws: What Testing Reveals

Twin-screw extrusion is the preferred method for compounding PLA and other biopolymers. But processing PLA is complicated because it’s sensitive to heat and shear. It’s also prone to hydrolytic degradation if moisture is present in molten PLA. Here’s what one machine builder’s trials revealed.

Read MoreThe Power of Numbers: Time to Step Up to Five Layers

Five-layer technology can provide processors with more productivity and greater flexibility to produce a wider range of products from a single line.

Read MoreFive-Layer Line Gives Processor More Flexibility, New Opportunities

Processor bumps it up from three-layers to boost quality, flexibility and enter new markets.

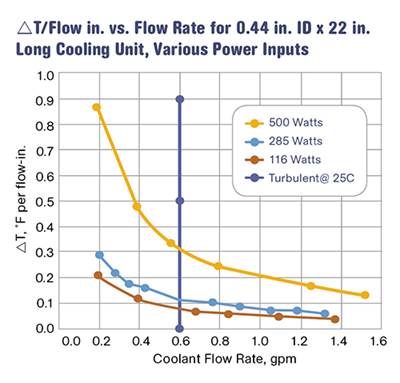

Read MoreLeverage Your Cooling Power

You can predict the amount of heat you'll need to remove from parts before ejection with reasonable accuracy if you know polymer thermal properties and certain other rules of thumb.

Read More