processing tips

‘Back to Basics’ Fuels More Innovation at Thin-Gauge Former

Shift from private to capital ownership give Tray-Pak a boost.

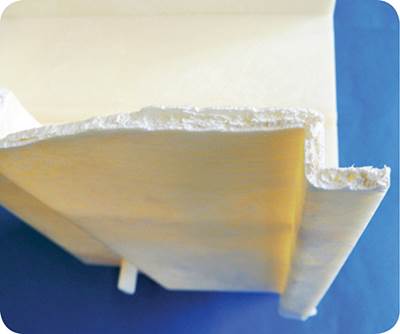

Read MoreLooking into Photovoltaic Film? Here Are Material & Die-Design Insights

The market for high-tech film or sheet used in solar modules represents a considerable opportunity for specialty extrusion processors looking to expand into high-end industries and capitalize on the global shift toward alternative energy.

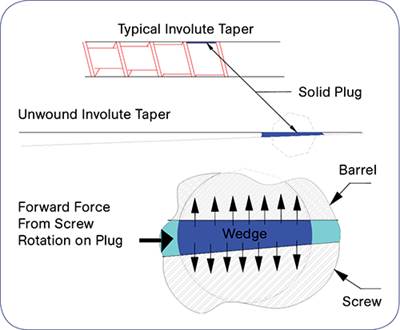

Read More‘Wedging’ Can Cause Severe Screw Wear

In a column I wrote for the July 2011 issue, I discussed the value of conducting “forensic” examination of worn screws when they are removed for clues to design flaws.

Read MoreWhat to Calibrate on Your Press

There are different approaches to meeting the goal of making parts identically. At the heart of all them is the process or the machine setup sheet. My bet would be you cannot find two that are identical.

Read MoreWorking with Color Concentrates

Because the consumer sees so many colored plastic articles, it is natural to assume that the process of achieving molded-in color is a simple one. Those of us in the industry know differently.

Read MoreMaking Parts Lightweight & Strong with New Technologies

One of the driving forces in technology is weight reduction.

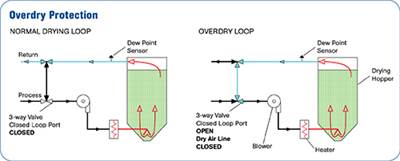

Read MoreCentral Drying Made Simple

Recent advances in technology have made the concept of drying in a central location—as opposed to right at the machine—more advantageous for certain kinds of processing operations.

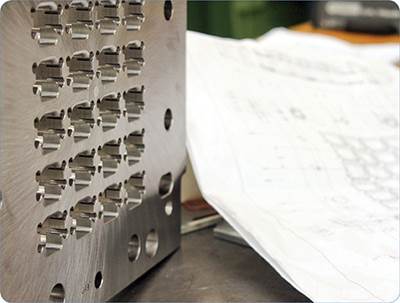

Read MoreGetting Into LSR--Part IV: How LSR Tooling Is Different

Building molds for rubber molding, and specifically liquid silicone (LSR ) injection, can be very challenging.

Read MoreWant to Slash Energy Costs? Learn How to Measure & Manage Them

Price pressure from consumers and rising energy costs have increased the importance for molders to reduce energy consumption, measured in kWh/kg of resin processed.

Read More