best practices

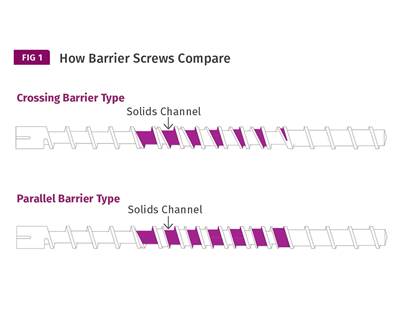

Barrier Screws: Not All Are Created Equal

Let’s take a deep dive into parallel and crossing types and see where each fit in.

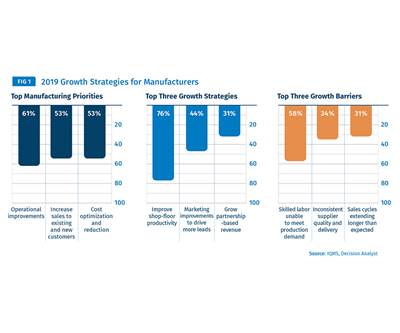

Read MoreProcessors Taking Pragmatic Approach to Industry 4.0

Recent survey reveals that processors evaluate any new technology—including Industry 4.0—by its contribution to improving operations and shop-floor productivity.

Read MoreHow to Manage Pressure Loss in Injection Molding

Achieving a process window wide enough to ensure consistent part quality depends on achieving sufficient pressure at end of fill.

Read MoreHow the Right Granulator Helps You Get the Most Out of Your Material

Not all granulator designs are the same, so which one is right for your application? The one you have today may have been purchased for an entirely different application and may not be best suited to your needs. Here are some things to think about that can help you decide what’s best for you.

Read MoreFive Factors to Consider When Molding PEEK

Are you a first-time molder of PEEK? Have you tried molding it and might be running into trouble? Take a look at five factors in the injection molding process that can help to avoid the need for troubleshooting when molding PEEK.

Read MoreExtruder Degassing: Is a Central System Right for You?

Centralization vacuum pumps have been used for many decades, most widely used in packaging. For extruder degassing the technology can be useful when several production lines are operated in parallel

Read MorePart Two: Determining Viscosity Data Using a Slit Die Viscometer

Using a slit-die viscometer connected to a lab extruder can generate accurate data on melt viscosity at various shear rates and different temperatures—a useful QC tool in processing.

Read MoreConveying Elbows Handle 40% Glass-Filled Nylon

Lighter and cheaper than cast alternatives, new stainless-steel conveying elbows utilize a plastics-specific geometry and proprietary internal coating to withstand filled materials.

Read MoreHow to Quickly Verify Your Machine & Process Setpoints

For a quick check of your process setup, the injection-pressure-vs.-time graph is your best tool.

Read MoreImplementing Automation Systems: How to Do It Right

If you’re thinking of putting a complex automation system for high-volume consumables into your plant, consider these tips on making sure both you and your supplier are ready to give it the best chance of success.

Read More