best practices

Part 1: The Basics of Tapered Interlocks

Various types of interlocks are available to molders. Here, we discuss the oldest and most common types of interlocks—those with a tapered or angular shutoff.

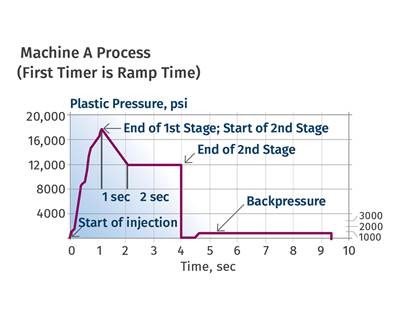

Read MoreGraphing Injection Pressure: What Should Pack & Hold Curves Show?

Are you sure your press is doing what you want? Visit your controller often to ensure your machines plot the pressure vs. time graph for all your processes. Here let’s focus on pack and hold.

Read MoreMolder’s Philosophy of ‘Giving Back’ Helps Attract New Employees

R&D Plastics participates in numerous programs to further plastics education with local universities and high schools. This effort breeds good community relations and helps attract new employees.

Read MoreUsing Decompression to Your Advantage—Your Questions Answered

Since the article on decompression has been published, I have received a few questions that I wanted to share with everyone.

Read MoreHow to Use 'Mapping' to Troubleshoot Blown Film Problems

Three real-world case studies show how processors solved common problems in blown film via the mapping technique.

Read MoreStrike the Right Balance in Process Cooling to Improve Product Quality & Profitability

Weigh planning methodology and today’s technology to cost-effectively address your process-cooling needs.

Read MoreHow to Avoid Unpleasant Surprises in Size Reduction

Size-reduction equipment doesn’t get much attention unless there’s a problem or an entirely new application challenge. So when it’s time to repair or upgrade, take these steps to avoid any unpleasant surprises.

Read MoreFollow These Steps to More Efficient Central Pneumatic Conveying

Depending on when you bought and installed it, there are ways to tweak your central pneumatic conveying system to improve its performance and save you some money.

Read MoreHow to Deal With Residual Stress in Molded Parts

Here are design, molding, and fixturing considerations to help you handle this unavoidable issue.

Read MoreSPE Adds New Categories for Thermoformed Parts Competition

Two new categories this year are parts produced with recycled/sustainable materials and those made using automation and new technology.

Read More