best practices

Don’t Get Caught in the Flash-and-Shorts Chase

Injection molding’s most common defects can have inverse correlation, where correcting one causes the other, leading to the “chase.”

Read MoreFollow These Tips to Sanitize Machine Controller Screens & Buttons

Keeping your workers safe from the coronavirus makes it extremely important to institute a sanitizing procedure on all touch surfaces of the controller, screen and operating panel. I did some research and here’s what I found.

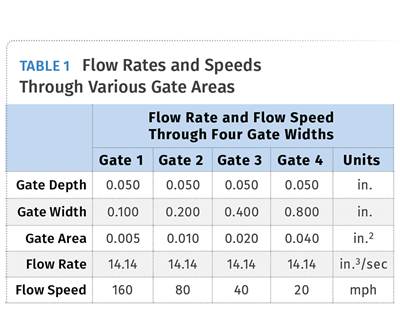

Read MorePart 1: How to Properly Size Gates, Runners and Sprues

Get the sprue, runner and gate sizes close to ideal the first time around—without spending a lot of time on extremely complicated formulas.

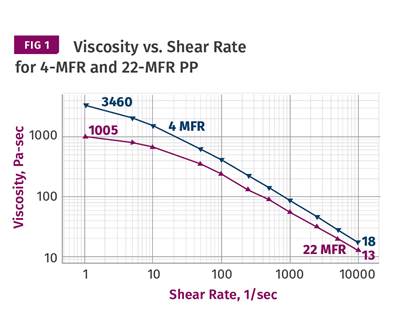

Read MoreTry This Lower-Cost Purging Method

You might be able to reduce purging times and save money by scheduling processing jobs in order of the increasing material viscosity. But to get started, you'll need shear rate/viscosity curves for your polymers.

Read MoreSPE Schedules First-Ever 'Virtual' ANTEC

Attendees can listen to keynotes and presentations live. Many presentations will also be recorded.

Read MoreHow to Optimize Usage of Recycled Material

Processors need to “engineer” feeding properties similar to virgin pellets into their regrind to efficiently and economically utilize more of their scrap.

Read MoreWhy—and How—You Should be Tracking Your Regrind

Ask yourself these questions to decide whether you need to implement a system to manage your scrap.

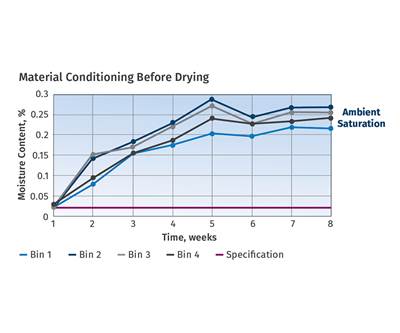

Read MoreUse a DOE to Improve Consistency of Your Resin-Drying Process

Conducting a drying design of experiments (DOE) will ensure your polymer is properly dried every time. Here’s how to do it.

Read MoreIn Search of a Universal Setup Sheet

Duplicating a process from one injection machine to another is frustrating and time-consuming. Develop a mold-specific setup sheet that works in all kinds of presses by differentiating plastic parameters from machine parameters and duplicating those plastic conditions from machine to machine, electric or hydraulic.

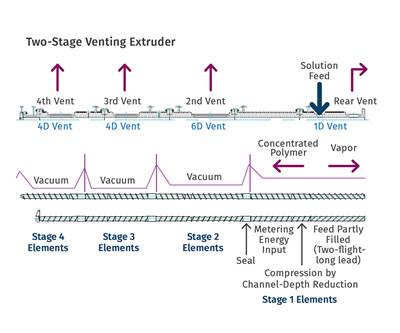

Read MoreCompounding: Part 1 of 2: Demystifying Devolatilization

Very little has been written about this critical topic, and most of what has been published is theoretical. Here’s some practical guidance to help you better understand the process and improve your operation.

Read More