best practices

When to 'Adapt,' When to Retool?

That is the question pipe and tubing processors typically confront when they specify a line for one product, only to have to add to the product mix when ´óĎó´«Ă˝ conditions change. Here are some tips to guide you to the right answer.

Read MoreHow to Prevent Nozzle Tip Leaks, Part 1

Instead of learning from your mistakes, stop making them in the first place.

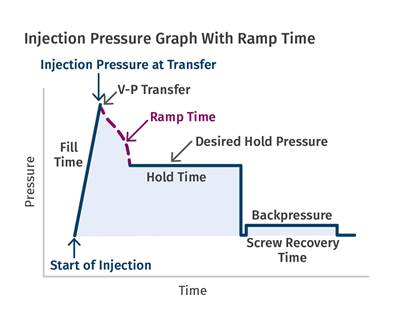

Read MoreV-to-P Ramp Time and Over-Travel

Many injection machines use ramp time to control the transition from injection pressure to hold pressure and reduce over-travel. Do you know how to set yours?

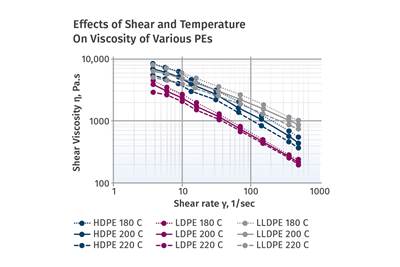

Read MoreUnderstanding Viscosity in Extrusion

Both the power-law coefficient and the consistency index must be considered to calculate viscosity.

Read MorePart 1: The Basics of Tapered Interlocks

Various types of interlocks are available to molders. Here, we discuss the oldest and most common types of interlocks—those with a tapered or angular shutoff.

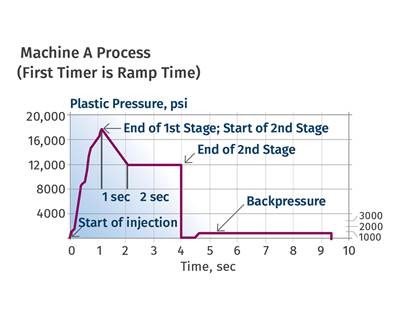

Read MoreGraphing Injection Pressure: What Should Pack & Hold Curves Show?

Are you sure your press is doing what you want? Visit your controller often to ensure your machines plot the pressure vs. time graph for all your processes. Here let’s focus on pack and hold.

Read MoreMolder’s Philosophy of ‘Giving Back’ Helps Attract New Employees

R&D Plastics participates in numerous programs to further plastics education with local universities and high schools. This effort breeds good community relations and helps attract new employees.

Read MoreUsing Decompression to Your Advantage—Your Questions Answered

Since the article on decompression has been published, I have received a few questions that I wanted to share with everyone.

Read MoreHow to Use 'Mapping' to Troubleshoot Blown Film Problems

Three real-world case studies show how processors solved common problems in blown film via the mapping technique.

Read MoreStrike the Right Balance in Process Cooling to Improve Product Quality & Profitability

Weigh planning methodology and today’s technology to cost-effectively address your process-cooling needs.

Read More