best practices

November 2020’s Most-Viewed Articles

These articles garnered the most reader attention among stories posted in November 2020 by Plastics Technology: implementing automation, gauging residence time, the history of polymers and more.

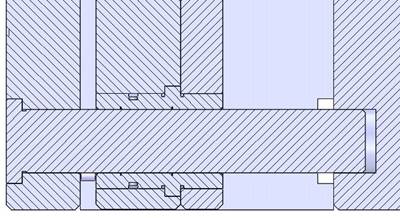

Read MoreTroubleshooting Pressure Fluctuations in Piston-Type Melt Filters

Piston filtration offers many advantages over other systems. While pressure fluctuations could be regarded as their weakness, there are many ways to avoid them, both from the mechanical and the process side. Small adjustment can make a huge difference in the overall performance and efficiency of the system.

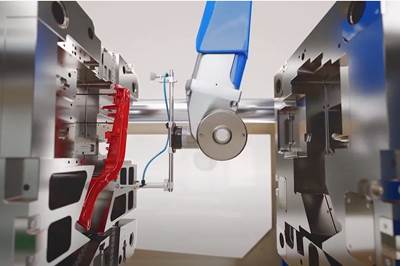

Read MoreHow to Automate High-Precision ‘Micro’ Insert Molding

What does it take to automate a horizontal injection molding cell to handle micro-sized inserts and molded parts? General-purpose top-entry robots and tooling may not be up to the job.

Read MoreHow to Plan and Implement Automation in an Injection Molding Plant

There is no “one size fits all” solution in automation. When considering what it would look like in your plant, hone in on the staff, products, space, and goals that are specific to you and the automation system that you will be installing.

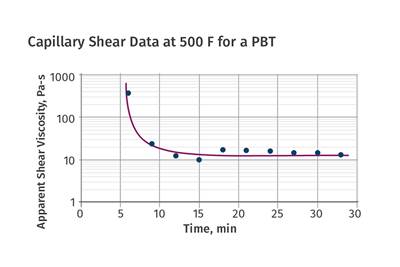

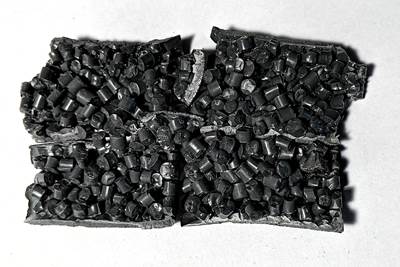

Read MoreResidence Time and Residence-Time Distribution—Part 1 of 2

Failing to calculate and accurately account for residence time can compromise material integrity before it’s even injected.

Read MoreInjection Molding: Understand the Link Between Feed Throat Temperature & Bridging

Save time and money by properly controlling the feed-throat temperature. In some cases—but not all—it can help you solve a bridging problem.

Read MoreShopping for a Barrel? Consider the Full Cost of Ownership

Beyond just the “invoice price” of a barrel, processors should consider factors like the composition of the inlay, quality of the backing material, straightness, concentricity, machining imperfections and packaging/handling, to understand the true cost of owning a barrel.

Read More'10 Things We’re Seeing in Machine Shops Right Now'

Metalworking shops and plastics plants make for interesting comparisons of their responses to the COVID-19 challenge.

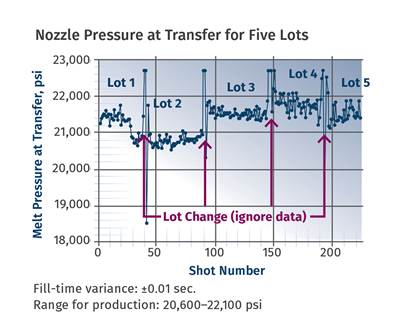

Read MoreHow to Know When Your Process is Ready to Make Acceptable Parts

Focus on six key metrics to help you determine when a process is lined out and stable enough to start production.

Read More