best practices

Finding People Is One Thing – Keeping Them Is Another

Everyone bemoans the difficulty of finding workers. Are you doing enough to hold onto the ones you have?

Read MoreLooking to Handle More rPET? Don't Overlook Your Conveying System

There is a lot of important process equipment in PET recycling plants, and pneumatic and mechanical transfer systems connect them all. Downtime due to poor transfer system design, incorrectly applied components, or the lack of maintenance should not be a fact of life. Demand more.

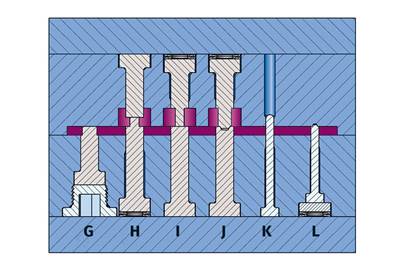

Read MoreHow to Form a Hole with a Core Pin: Part 2

Prevent wear, flash, and mold damage with these design methods.

Read MoreWhy Careful Hydraulic Oil Maintenance is Critical to Molding Machine Reliability

Here are the essentials on how to prevent one of the main threats to long-term reliability of your injection molding machines.

Read MoreWorkforce Instability and How to Avoid It

How employers can support employees who live in economic instability.

Read MoreSecrets of Quick Part-to-Part Changeovers

Part-to-part changeovers can be fast only with proper advance planning. Here’s what you need to know to convert from sluggish to swift in job changes.

Read MoreWhat You Need to Know About Blade Ejectors: Part 3

Follow these guidelines to prevent premature wear, flash and galling. The focus here is on corner radii.

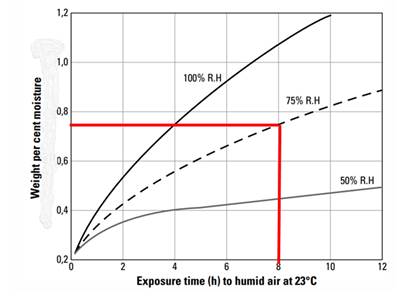

Read MoreFollow These Seven Management Tips for More Consistent Resin Drying

Equipment and advice sure help, but ultimately, good management makes the difference.

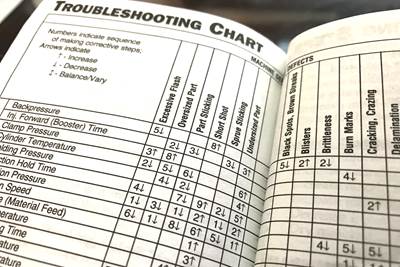

Read MoreApply the Power of a Troubleshooting Checklist to Your Process

Pocket guides provide processors an injection molding “crib sheet,” but in a process with thousands of interactions, applying if-this/then-that logic can’t always get you to a problem’s root cause.

Read MoreHeard of Design for Manufacture…How About Design for Maintenance?

Contract manufacturer Canon Virginia (yes, that Canon) used a webinar to introduce what it calls DFM2— Design for Manufacture and Design for Maintenance.

Read More