best practices

Five Ways SPC Can Improve Performance

Statistical process control (SPC) can help plastics processors determine the factors responsible for product quality variation and provide a roadmap for improving the production process.

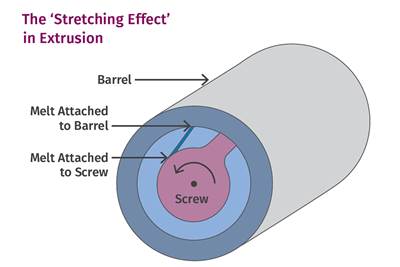

Read MoreUnderstanding the Effect of Polymer Viscosity on Melt Temperature

Every processor should get hold of the viscosity curves for the polymers they use or contemplate using in their operations, and learn how to read them.

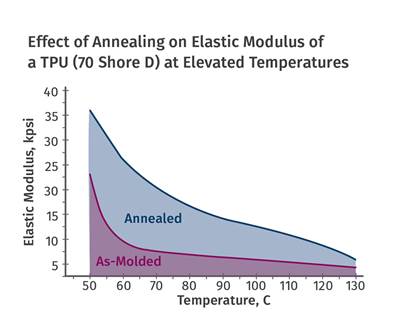

Read MoreMaterials Part 6 of 7: Annealing Tips for Thermoplastic Polyurethanes

TPUs form physical, rather than chemical, crosslinks that can be broken by reheating. Formation of these crosslinks can be sped up by annealing, which improves a variety of properties.

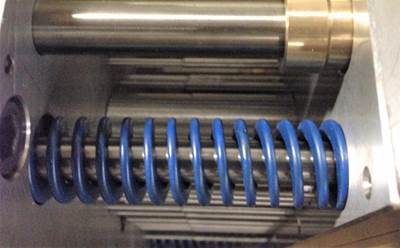

Read MoreFollow These Purging and Preventive Maintenance Tips for Your Screws and Barrels

Processors can extend the life of equipment and improve productivity by coupling a preventive-maintenance program for their screws and barrels with routine use of chemical purging compounds..

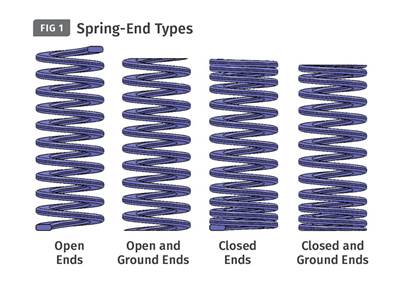

Read MoreTooling: Back to Basics On Die Springs--Part 2

Follow these steps for proper die-spring selection and installation.

Read MoreHow and Where Twin-Screw Extruders Fit in Recycling

When utilized in a thoughtful way, the corotating intermeshing twin-screw extruder can transform recycled materials into value-added products and parts. Here’s what you need to know, and some real-world examples of the technology deployed for both post-industrial and post-consumer recycling.

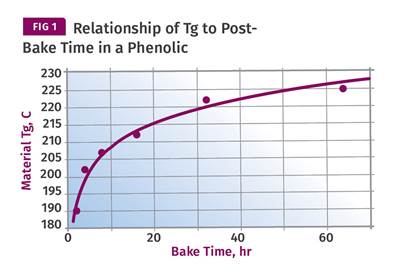

Read MoreMaterials Part 5: Annealing Tips for Crosslinked Polymers

As with semi-crystalline thermoplastics, annealing can be used in thermosetting polymers to obtain a level of crosslinking that may not be possible within the molding cycle.

Read MoreTooling: Back to Basics on Die Springs Part 1

Some molding shops insist that all of their molds have springs to return the ejector plates. And there are lots from which to choose. Here we’ll focus on compression die springs for injection molds.

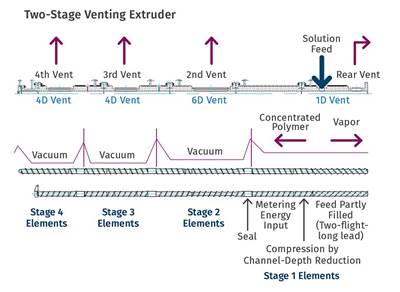

Read MoreDemystifying the Devolatilization Process

Here are some practical guidance and simple tools to help you better understand the process and improve your operation.

Read MoreBack to the (Re)Grind

Some amount of scrap—generated in startup, shutdown or defective parts—is inevitable. How can you reclaim regrind into new profitable parts?

Read More