best practices

The Top 10 Most-Viewed Plastics Technology Articles of 2018

Sinks, flash, gels, weld lines—many of the most-viewed articles at PTOnline.com in 2018 offered processors advice on how to deal with some of plastics most nettlesome problems.

Read MorePlastics Technology’s Most-Viewed Columns of 2018

Here are the expert columns that visitors to PT’s site viewed the most in 2018, covering mold and melt temperatures; shot sizes; barrel capacity; material properties and more.

Read MoreProcess Capability and the ‘Hesitation Effect’

Understanding the concepts of pack and hold and applying them during process development is critical for molders to achieve consistent part quality.

Read MorePart 1: Heat Deflection Temperature vs. Dynamic Mechanical Analysis

Does the industry need a better way of reporting the temperature-dependent behavior of plastics? With DMA, it already has one. But it’s been glacially slow to catch on.

Read MorePART 2 OF 2: Tricks of the Trade on RTOs, RSOs

They have a lot more to offer molders than just shutting off a cavity. Let’s take a closer look.

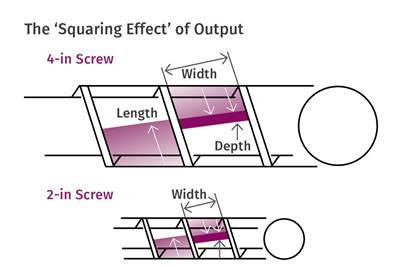

Read MoreUnraveling the Complexity of Single-Screw Scale-Up

Variables such as shear rates, melting rate, residence time and conductive heating are all influenced in the scale-up.

Read MorePART 2: The Importance of Consistent Fill Time

To make identical parts, you need to keep fill time constant. In part one we covered the why. Here’s the how.

Read MoreWorldwide Switch to New Gauging System Pays Off for Haartz

Leading supplier of sheet and roll stock for automotive applications reevaluated its thickness-measurement technology in 2012, and now has 15 scanners in place worldwide from one supplier.

Read MorePart 1: The Importance of Consistent Fill Time

To make identical parts, you need to keep fill time constant. Here’s why.

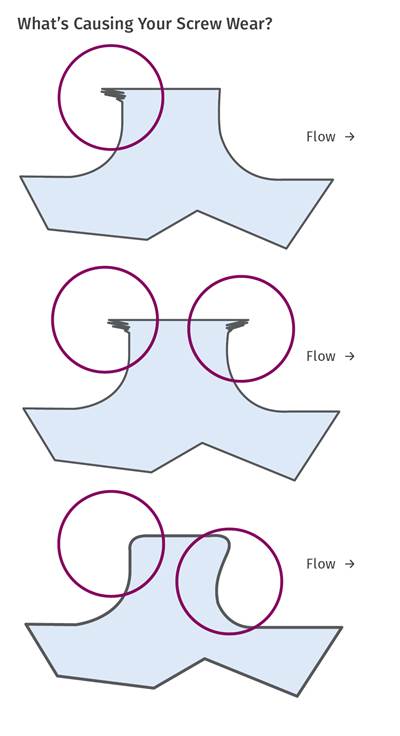

Read MoreTelltale Signs of Screw Wear

Determining the cause of wear is the first step in eliminating it.

Read More