best practices

Tricks of the Trade on RTOs and RSOs

The more you know about these runner diverters and shutoffs, the more you’ll use them. Here’s how to put them to work in your mold..

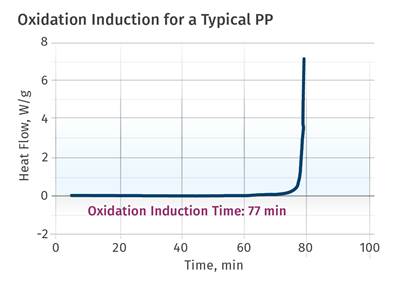

Read MorePart 11: A Processor's Most Important Job

It’s the processors job to ensure molded parts contain enough stabilizer to perform to the expectations of the end use.

Read MoreA Gel By Any Other Name...

Gels…unmelt…contaminants…inclusions…whatever you call them, you want to avoid them. Proper maintenance and good housekeeping—lids on boxes, closed hopper doors, core-free reclaim systems—go a long way towards defect-free product.

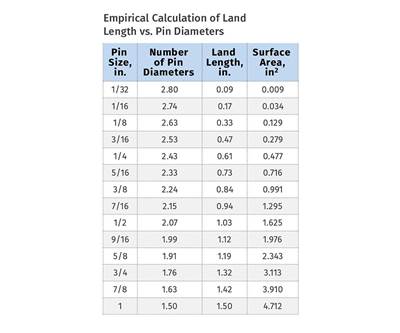

Read MoreWhy Ejector Pins Break and How to Prevent It: Part 4

In this installment the focus is on bearing length, clearances, keying, and machining.

Read MoreTooling: Why Ejector Pins Break and How to Prevent It, Part 3

Here we focus on forces, friction, surface finish, and lubrication.

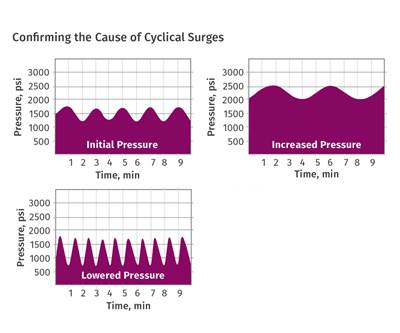

Read MoreExtrusion: Head Pressure and Output Stability

Use drag- and pressure-flow equations to analyze fluctuating output.

Read MoreInjection Molding: Sliding vs. Locking Ring—Which Non-Return Valve Is Right for You?

The locking-ring style appears to dominate the market, as most believe it makes a make a better seal and leaks less. But is this really so?

Read MoreA Processor's Most Important Job, Part 9: Avoid Molded-In Stress

How to establish molding conditions that minimize internal stress in a part.

Read MoreUp to Snuff on Scientific Molding? Then it’s Time to Mold ‘Systematically’

Scientific molding is centered around learning about key molding principles and theories. The strategic application of those principles and theories is what’s known as systematic molding.

Read MoreConveyor Upgrade Keeps Currier on Track

Processor’s switch to modular plastic belt conveyors increased efficiency in bottle making by eliminating downtime.

Read More