Tooling Know-How

TOOLING: Repairing Molds in the Press: Part 3

This is the final part of a series on tooling in the press. This column will cover repairs that can be accomplished in the press.

Read MoreTOOLING: Designing Molds for Easy Cleaning & Maintenance in the Press

Pay attention to water leaks and rust, proper grease selection, vent buildup, and checks for wear.

Read MoreTOOLING: Designing Molds for Easy Maintenance in the Press, Part 1

Attention to design of cooling, ejection, and slides can save downtime and maintenance headaches.

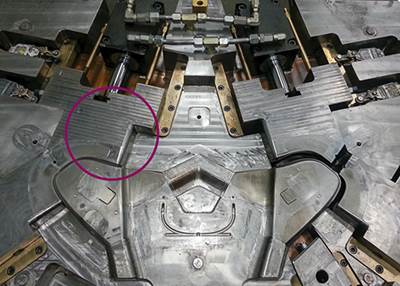

Read MoreTOOLING: Dealing with Lifters--Part 2

This installment delves into more detail on some variables of design and fitting/timing of the lifters, which can cause issues or failures during molding.

Read MoreTOOLING: Having Trouble with Lifters?

Lifters can cause tool maintenance, repair, and processing issues if not designed properly. Here we begin a series on how to avoid all this.

Read MoreTOOLING: How to Vent Mold Details

Principles to follow in venting bosses, ribs, pins, cores, slides, and lifters.

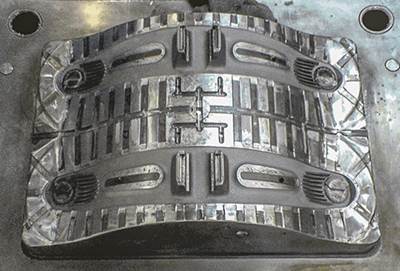

Read MoreTOOLING: Venting: Where And How Deep?

After last month’s introduction to the subject, let’s get into the details on vent depths, land lengths, and the alternatives to perimeter venting.

Read MoreTOOLING: Venting: A View From the Trenches

Venting is a prime culprit for molding problems, partly because toolmakers and process techs have different ideas of what’s needed.

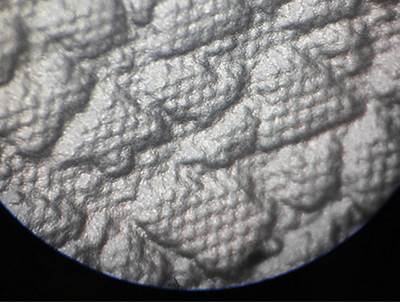

Read MoreTOOLING: Clearing Up the Mysteries Of Mold Texture

It’s a subject not widely understood by molders and it affects more than just part appearance.

Read MoreTOOLING: What You Can Do About Mold Buildup

It depends on the materials and additives you use, and the kinds of mold detail, but adequate venting, not overheating the material, and mold coatings are your best defenses.

Read More