Tooling Know-How

The Value of 20 Bits of Data

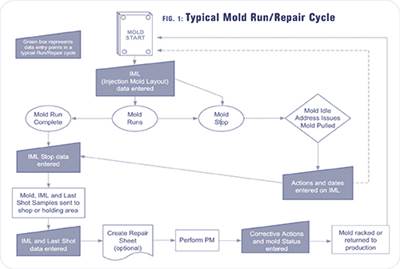

With these 20 bits of data, toolrooms can drastically lower the cost of keeping molds running and improve mold reliability and tooling life while reducing breakdowns and molding better parts.

Read MoreSafety Sense in the Shop

Running a clean, organized, professional, and safe shop requires a team effort that includes an awareness of unsafe practices and equipment that need to be eliminated, replaced, or improved, along with the accountability of all to identify and document safety issues.

Read MoreTool Room Management: How To Lead Your Team

Real progress in a mold shop won’t be made without a qualified and motivated “driver at the wheel” who diligently searches for, and implements, continuous-improvement solutions.

Read MoreThe Tools of Tool Maintenance

The root cause of many mold and part issues are ultimately determined by the ability to measure something within one or two tenths of a mil. Readings with precision measuring tools can determine whether a tooling component is to be reused, reworked, or scrapped out.

Read MoreHow To Size & Calibrate Profile Parts

Doing it right is critical to maintaining profile dimensions.

Read MoreKnow the Three F’s Of Profile Tooling Design

Designing an extrusion profile and ultimately the die design and sizing equipment cannot be executed successfully without a full understanding of the customer’s quality expectations or specifications.

Read MoreCreate a Maintenance Work (Bench) Cell

Get better results by improving the organization of your mold-maintenance operation.

Read MoreTooling: Setting Up Shop: Part III

Our last column covered shop size and bench requirements for a 50 x 50 ft mold-repair shop that will have a MPP (Mold Pull Pace) of approximately 25 to 30 multi-cavity molds a week and employ four repair technicians in a six-bench layout.

Read MoreTooling: Setting Up Shop—Part II of III

Many repair shops in molding facilities are too small, poorly lit, and inefficiently designed.

Read MoreTooling: Setting Up a Mold Shop: Part I

I had a toolmaker once tell me he used to slam his hand in his car door before work every morning just to get him in the right frame of mind to work in his shop.

Read More