Tooling Know-How

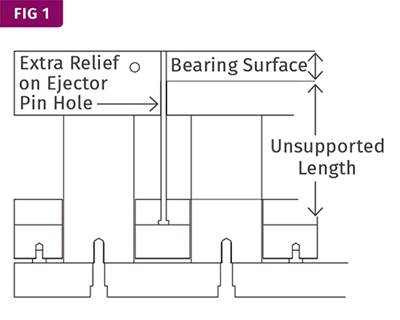

TOOLING: Ejectors: Watch That ‘Unsupported Length’

It may be an unfamiliar term, but it’s the key to preventing ejector-pin deflection and breakage

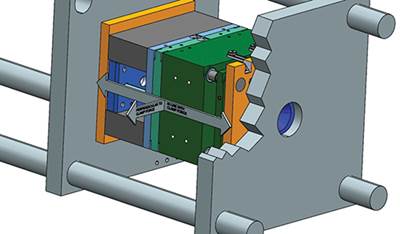

Read MoreTOOLING: Designing the Tool for the Material

To design a mold for the widest processing window and the fewest problems, start by considering the conditions imposed by the material being run.

Read MoreThe Importance of Gate Geometry

Gate size and shape—unlike gate location—don’t often get the attention they deserve. Many common assumptions about gate geometry deserve to be challenged

Read MoreTOOLING: Flash-Free Molding: Part Two

Parting-line maintenance, mold spotting, and machine conditions can all contribute to flash.

Read MoreTOOLING: Flash-Free Molding: Part 1

A robust process window relies a lot on tooling. So it stands to reason that making a tool change to address issues provides a more robust solution

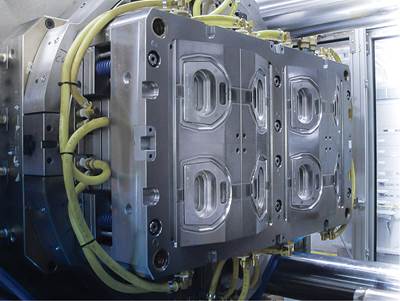

Read MoreTOOLING: Balancing the Heat Budget In Injection Molds

Basic formulas for how much heat you must pull out of the mold to achieve a set cycle time

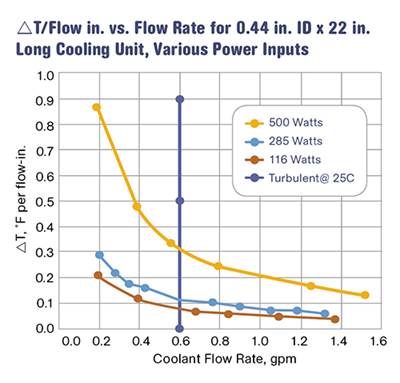

Read MoreLeverage Your Cooling Power

You can predict the amount of heat you'll need to remove from parts before ejection with reasonable accuracy if you know polymer thermal properties and certain other rules of thumb.

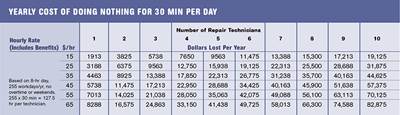

Read MoreMaintenance Training? Show Me the Money

Training works best if a goals are set and a plan is established to meet them.

Read MoreMaintenance Terms of Endearment

Look closely at your company鈥檚 mold maintenance language and formalize your approach to create a clear and concise picture鈥攐ne that can be measured.

Read More