Tooling Know-How

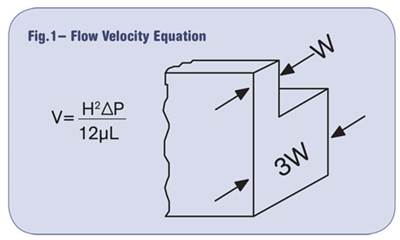

Tooling: The Science of Profile Die Balancing

In our last column, we discussed the five things profile extruders need to know about profile die design鈥攑roper land length, land-length ratio, drawdown, considerations for sensitive materials, and decompression.

Read MoreDetermining Maximum Mold Cycle Counts

The first production meeting with my new employer went something like this: “We want you to establish a preventive maintenance program that is based on cycle counts for all our molds.” Before I could launch into an explanation of how best to determine maximum cycle counts, I was hit with this: “So, how many cycles do you think our molds can safely run before we need to clean them?”Leaving my crystal ball at home and unable to get my x-ray vision working, there was no way to answer that question with any accuracy.

Read MoreWhen Assembling Molds, Patience is THE Virtue

Installing and fitting close-tolerance tooling requires patience, a steady hand, attention to detail, and the ability to “read” resistance.

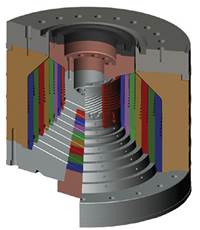

Read MoreCommunication Is Key in Designing Blown Film Dies

Over the years I have bought, designed, or helped design quite a number of blown film dies.

Read MoreYou Think You Know Your Molds? Try These 10 Questions to Find Out for Sure

A mold repair technician’s job has always been to make molds run—anyhow, any way.

Read MoreTooling Know-How: Five Tips on Profile Die Design

A poorly designed profile die—one that does not permit the part to be extruded with the same dimensions from run to run—coupled with a lack of understanding of the extrusion process, is a recipe for scrap generation.

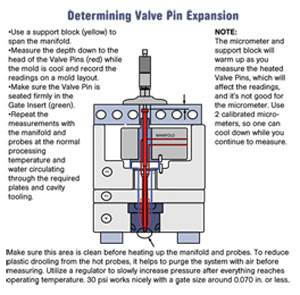

Read MoreTooling Know-How: Troubleshooting Defects--Part II: Hot-Runner Long Gate Vestiges

Last month, we discussed the general issues of an organized and disciplined process of troubleshooting and correcting mold defects.

Read MoreTroubleshooting Defects: Part I

Like the three other aspects of a typical mold clean/repair job (disassembly, cleaning, and assembly) there is usually more than one way to skin the cat of troubleshooting and correcting defects.

Read MoreThe Eight Stages of Mold Repair

While the mold was still being disassembled, two “cleaners” began pulling tooling out of plates and putting them into buckets in preparation for a good scrubbing—and I mean a scrubbing.

Read More