Stretch Blow Molding

Change Over High-Output PET Blow/Fill/Cap Lines in Just One Week

Sidel delivered seven new PET bottle formats across two integrated water and soft-drink bottling lines within a week apiece.

Read MoreFaster, More Automated Changeover for PET Bottles

Sidel has updated its Bottle Switch technology for its latest PET stretch-blow machines, adding robot assistance.

Read MoreFaster Neck Changes Add Flexibility to Aseptic PET Blow Molding

KHS machines now can change neck sizes and associated components in one-third the former time.

Read MoreUltra-Compact PET Machine For 12 L in Two Cavities

New size of all-electric reheat stretch-blow machine for large PET bottles debuted from 1Blow at K 2022. It retains the company’s signature small footprint and energy-sparing features.

Read MoreHow Was K 2022 for Blow Molding?

Over a dozen companies emphasized sustainability with use of foam and recycle, lightweighting and energy savings, along with new capabilities in controls, automation and quick changeovers.

Read MoreComprehensive Optical Inspection for PET Preforms

Delta Engineering teams with Intravis to inspect preform mouth, body, thread and color.

Read MoreAll-rPET Bottles with Glued-in Handles Save Material

At K 2022, KHS is showing a 2.3 L PET bottle with glued-in handle that offers 10% material savings and other advantages over clip-in handles. Bottle and handle are both 100% rPET.

Read MoreMold Opaque White PET Bottles – Without Pigment

Trexel and Husky are cooperating on molding recyclable opaque white preforms for PET bottles, which provide a light barrier using foam instead of pigment.

Read MoreAll-Electric Machines & Blow Molding Automation Featured at K 2022

Magic MP spa will present new EBM auto adjustment, electric accumulator-head technology, a larger ISBM machine, a quick-mold-change system, and robotic product handling/palletizing at this month’s show in Düsseldorf.

Read MoreFirst Integrated PET Bottle Blowing, Inspection & Palletizing Machine

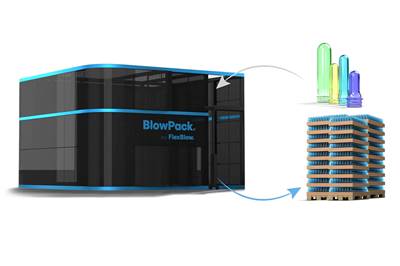

During K 2022, FlexBlow will demonstrate BlowPack at its plant in Lithuania. It’s described as a “world’s first” integrated system in one machine.

Read More