Faster Neck Changes Add Flexibility to Aseptic PET Blow Molding

KHS machines now can change neck sizes and associated components in one-third the former time.

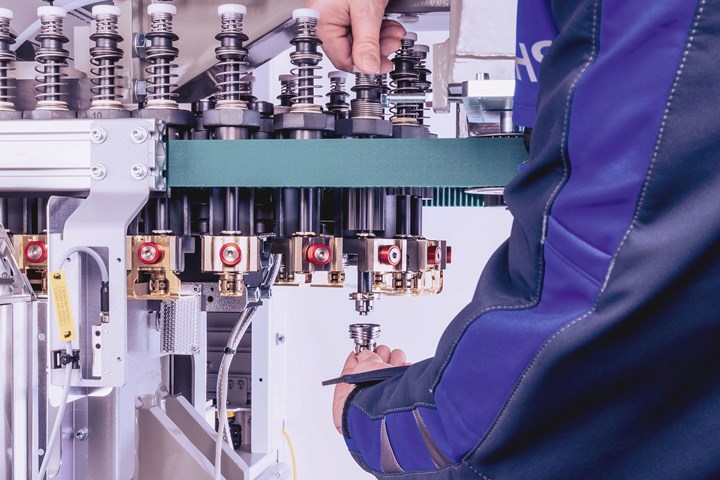

Quick changes of neck sizes allow flexible production of aseptically filled beverages and juice (38 mm) and carbonated soft drinks (28 mm) on the same blowing-filling-capping line. (Photo: Frank Reinhold)

If you wished to stretch-blow mold aseptically filled PET bottles for beverages and juices, which typically require 38-mm bottle necks, on the same line as bottles for carbonated soft drinks with 28-mm necks, you might have faced changeover times involving multiple workers for as long as 4 hr. Until now, that is.

KHS has addressed the need for more flexible production of multiple neck sizes on aseptic PET blowing-filling-capping lines by analyzing the ergonomics of every step of the process and introducing numerous modifications to components of its equipment in an integrated line like the InnoPET BlowFill.

For example, magazines were installed that stop the operator from having to leave the machine repeatedly to fetch change parts. KHS also replaced the grippers to reduce the number of screws to be loosened and tightened. Of particular importance, newly developed mandrel heads can be removed simply by pressing a release spring. With all these and other changes, the time needed for two operators to convert the KHS InnoPET Blowmax 16 stretch-blow molder — which has around 170 mandrel heads and shields to be replaced—has been cut by two-thirds to about 86 min, including the preform infeed.

A new feature on KHS InnoPET Blowmax machines is mandrel heads that are released by simply pressing on a spring. (Photo: Jörg Schwalfenberg)

KHS also modified the filler and capper. For example, there are now two cap feeds, one for each neck diameter, so no conversion is required.

KHS says these modifications offer customers “totally new options in their production planning.” For example, they allow molders to produce smaller batches of different bottles on a single line much more efficiently. There are also new advantages for customers that produce just-in-time, loading finished containers straight onto the truck without any interim storage.

Related Content

-

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

-

Processing Megatrends Drive New Product Developments at NPE2024

It’s all about sustainability and the circular economy, and it will be on display in Orlando across all the major processes. But there will be plenty to see in automation, AI and machine learning as well.

-

How to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.