First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

Vilsa in Germany has adopted rPET bottles with KHS FreshSafe PET Plasmax interior glass coatings for all sizes of its bottles for mineral water as well as juices, flavored water and carbonated soft drinks. Photo Credit: KHS

German spring water and soft drink producer has achieved what’s said to be a world first by demonstrating that even mineral water can benefit from a wafer-thin glass coating inside PET bottles. The company supplies premium mineral water containing various levels of carbonation, as well as fruit spritzers, soda pop and “near water” (flavored water) beverages. Vilsa is particularly proud of the pure, natural flavor of its spring water afforded by its pH and “gentle,” low-sodium mineral content. According to a Vilsa source, the extra barrier provided by the interior glass coating preserves carbonation and also prevents introduction of off-flavors — such as from acetaldehyde in the PET. In addition, Vilsa’s fruit spritzers benefit from oxygen protection provided by the glass coating.

In 2019, Vilsa switched all its nonreturnable bottles to rPET. Adding the coating technology furthers the company’s drive for sustainability, because the glass coating — unlike the use of additives to improve PET barrier — enables full bottle-to-bottle recycling as the interior coating is completely washed off during the reclaim process. Consequently, the company has adopted interior glass coatings for all its nonreturnable PET containers from 0.5 to 1.5 L. The first coated bottles were distributed to retailers this autumn.

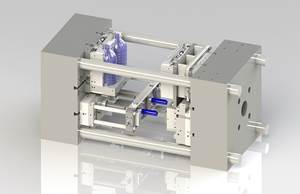

Vilsa combined a KHS InnoPET Blomax stretch-blow molder with a Plasmax barrier coating unit to form an InnoPET FreshSafe block capable of 24,500 bph. Photo Credit: KHS

At its mineral-water plant in Bruchhausen-Vilsen in Lower Saxony, Vilsa installed the latest-generation KHS innoPET Blomax stretch-blow molder. That unit was later combined with a KHS FreshSafe PET Plasmax barrier unit to form an InnoPET FreshSafe block. After stretch-blowing, cooling and transfer, the PET bottles are interior coated according to the Plasmax PICVD (plasma impulse chemical vapor deposition) process, which was first used in the pharmaceutical industry. The bottles are turned upside down and passed into the coating chamber, where a reaction gas mixture is introduced into the bottles in a vacuum and then is transformed into a plasma (ionized) state by microwaves. The result is a deposit of silicon dioxide (glass) inside the container — the coating is less than 0.1 microns (100 nm) thick and chemically bonded to the inside wall. The coating is completely transparent and flexible, so it will not flake off when the bottle is flexed, according to KHS. The coating separates from the PET only in the recycling process.

At Vilsa, bottles are blown and coated at rates as high as 24,500 bph. The most popular nonreturnable format is the 0.75 L bottle.

A number of well-known bottlers of juices and carbonated soft drinks have used Plasmax barrier technology for years, but Vilsa is the first to use it for mineral water. KHS specialists ran extensive simulations to achieve perfect distribution of the thin glass coating in Vilsa’s bottles. KHS Bottles and shapes technicians defined the exact recipe for each container size, product and CO2 level.

According to KHS, full recyclability of FreshSafe coated PET bottles has been confirmed by the European PET Bottle Platform (EPBP) and North America’s Association of Plastic Recyclers (APR). The coating’s suitability for use with foods has been certified by the U.S. FDA.

Related Content

At NPE, Cypet to Show Latest Achievements in Large PET Containers

Maker of one-stage ISBM machines will show off new sizes and styles of handled and stackable PET containers, including novel interlocking products.

Read MoreHow to Extrusion Blow Mold PHA/PLA Blends

You need to pay attention to the inherent characteristics of biopolymers PHA/PLA materials when setting process parameters to realize better and more consistent outcomes.

Read MoreThin, High-Performance Nylon/PE Barrier Film for Thermoformed Packaging

Südpack’s Multifol Extreme film is well suited for greasy, protein-rich and frozen foods

Read MoreMultilayer Solutions to Challenges in Blow Molding with PCR

For extrusion blow molders, challenges of price and availability of postconsumer recycled resins can be addressed with a variety of multilayer technologies, which also offer solutions to issues with color, processability, mechanical properties and chemical migration in PCR materials.

Read MoreRead Next

All-rPET Bottles with Glued-in Handles Save Material

At K 2022, KHS is showing a 2.3 L PET bottle with glued-in handle that offers 10% material savings and other advantages over clip-in handles. Bottle and handle are both 100% rPET.

Read MorePlasma “Glass” Barrier Coating Developed for Reusable PET Bottles

IKV and KHS Corpoplast in Germany collaborate on SiOx barrier coating that can withstand caustic washing for multi-trip PET bottles.

Read More3D Planning Visualizes New Machine & Line Layout

3D visualization of new PET bottle machines and complete packaging lines in plant environments ensures a good “fit.”

Read More