First Integrated PET Bottle Blowing, Inspection & Palletizing Machine

During K 2022, FlexBlow will demonstrate BlowPack at its plant in Lithuania. It’s described as a “world’s first” integrated system in one machine.

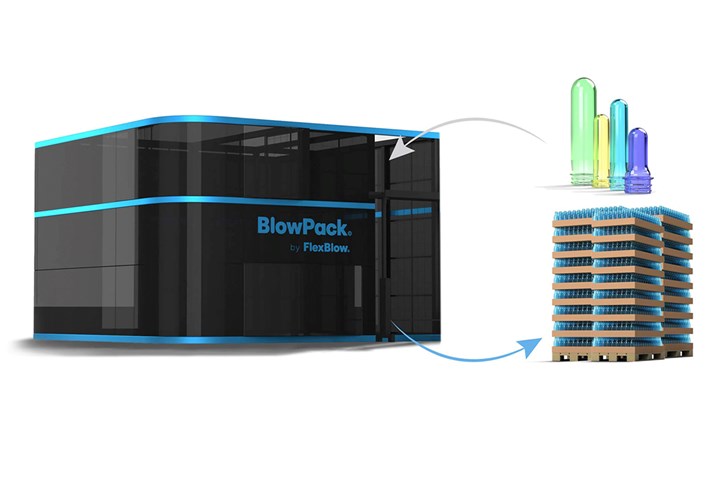

“Load the preforms in the morning and collect strapped pallets of containers in the evening.” BlowPack reportedly occupies half the floorspace of a conventional layout. (Photo: FlexBlow)

FlexBlow (UAB Terekas) of Lithuania (flexblow.com) has introduced a patented innovation that it describes as “the world’s first” integrated combination of PET bottle blowing, quality control and packaging in one compact machine. BlowPack is the name of this turnkey system that combines a two-stage stretch-blow molder, leak detector and palletizer into what’s said to be the “most compact end-to-end system in the industry,” occupying only half the floorspace of a conventional layout.

“Load the preforms in the morning and collect strapped pallets of containers in the evening. With BlowPack, we took automation a leap forward,” claims Gintautas Maksvytis, CEO of FlexBlow. He adds that 100% inspection is combined with automation to remove any unqualified containers before packaging.

The stretch-blow machine in this system – as with other FlexBlow machines – reportedly can be changed over from container sizes of 50 ml to 6 L, or from conventional blowing to hot-fill, in just 30 min.

This new three-in-one system will be demonstrated live at the company’s plant during the K 2022 show in Dusseldorf in October.

Related Content

-

First Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

-

Measuring Multilayer Plastic Containers Made Easier With Today's Ultrasonic Gauges

Ultrasonic gauge technology has evolved to simplify measurement of very thin layers in plastic containers. Today’s gauges with high-frequency capabilities and specialized software can make multilayer container measurement quick and easy for ordinary users.

-

Flexible-Film Processor Optimizes All-PE Food Packaging

Tobe Packaging’s breakthrough was to create its Ecolefin PE multilayer film that could be applied with a specialized barrier coating.