Sheet Extrusion

Plastics Technology's Drying Supplement

Learn from the experts, including savvy processors, on how to get drying done right.

Read MoreGranulate or Shred: Which Makes Sense for You?

That is the size-reduction question confronting many processors today. Look here for some guidance.

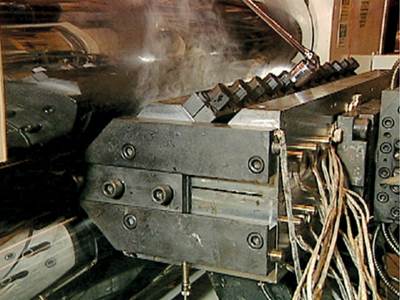

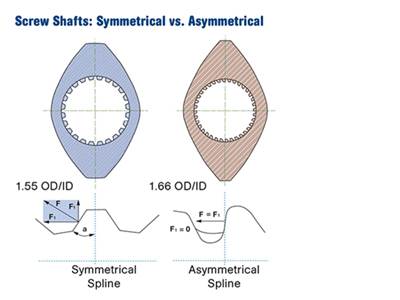

Read MoreEXTRUSION: Effect of the Screw Flight On Melt Temperature, Energy Use

So-called rules of thumb regarding the design of flight clearance and width do not consider the temperature effect, both from the point of view of melt temperature and energy efficiency.

Read MoreOctal to Start PET Sheet Extrusion in Ohio

APET sheet to be made exclusively from sheet flake.

Read MoreA Better Way to Balance Die Flow

Use temperature adjustments before making any mechanical tweaks.

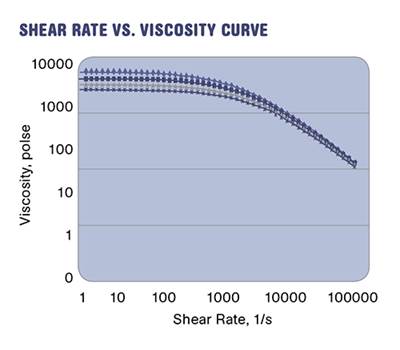

Read MoreCompounding PLA on Twin-Screws: What Testing Reveals

Twin-screw extrusion is the preferred method for compounding PLA and other biopolymers. But processing PLA is complicated because it’s sensitive to heat and shear. It’s also prone to hydrolytic degradation if moisture is present in molten PLA. Here’s what one machine builder’s trials revealed.

Read MoreUse Your Gauge to Solve Processing Issues Upstream

Gauging systems have an often-overlooked but equally important role beyond measuring web thickness: They can be used as a diagnostic tool to troubleshoot the process. Here's how.

Read MoreTop 10 Extrusion Items in 2013

Here's a quick rundown of things that caught my eye--and likely the attention of extrusion processors, in 2013.

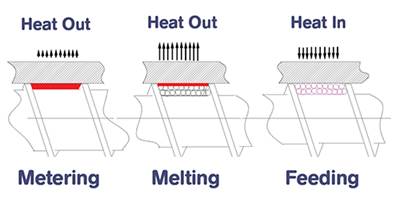

Read MoreTelltale Temperatures

Here's how to get a 'feel' for a screw design without actually seeing it. And how to use this information.

Read MoreExtrusion/Compounding at K 2013: Having It All

Extrusion processors no longer need to chose among speed, quality, and flexibility, based on exhibits at K 2013.

Read More