Sheet Extrusion

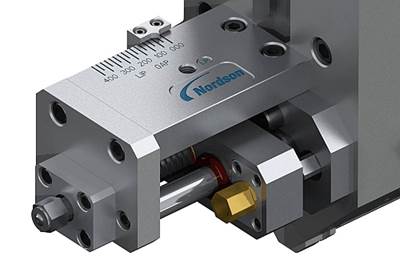

‘Breakthrough’ Tech Allows for Fast Sheet-Thickness Changes

New system uses a single-point adjustment to change the lip gap and modify the lip land length at the same time.

Read MoreEXTRUSION AND COMPOUNDING AT NPE: The Word Is ‘More’

As in speed, power, quality, flexibility, layers, and efficiency. Those are the trends across all extrusion processes.

Read MoreHow to Split & Clean Flat Dies

Notice a drop-off in quality of your flat film or sheet? It may signal that a die ‘split-and-clean’ is due. Here’s how to get going.

WatchAre Fillers and Pigments Impacting Your Processing Parameters?

As parts are loaded with higher and higher levels of fillers, pigments, and more, processors don’t always consider the impact these additives have on production.

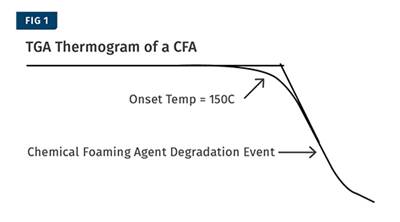

Read MoreHow Characterizing and Modeling Chemical Foaming Agents Can Help Your Process

Knowing ahead of time what will happen when your CFA produces gas can help you design or improve your process to boost quality and cost effectiveness.

Read MoreOn Site: 140 Years…And Growing Stronger

Now in its fifth generation of family ownership, this sheet extruder isn’t all about output. Its focus is on creating solutions in highly customized markets that aren’t immediately associated with sheet.

Read MoreNew Extrusion Equipment Combines U.S. Management with Chinese Production

Starting up in 2011, Uway Extrusion has begun its commercial push this year, with plans to exhibit at NPE2015 next March.

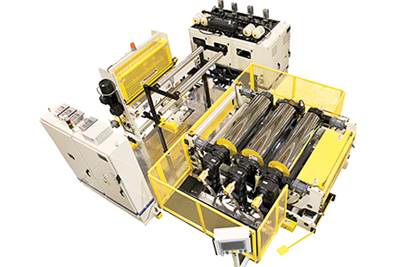

Read MoreOptimizing Thin-Gauge Sheet for In-Line Thermoforming

Processing thin-gauge sheet for in-line thermoforming poses unique challenges. Here’s how to cope with them.

Read MorePlastics Pioneers Association Adds Four Members

Founded in 1944, PPA is a non-profit organization with a roster about 200 members, all of whom have at least 25 years of experience in plastics.

Read More