scientific molding

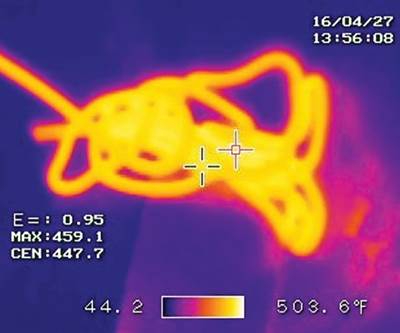

Unraveling the Mysteries of Melt Temperature

Infrared technology can provide consistent and accurate readings of melt temperature. Here’s how to use it.

Read MoreFaster Is Not Always Better—Optimize Your Molding Cycle

It is possible for machines to run too fast, so find the sweet spot where maximum output overlaps with good parts.

Read MoreINJECTION MOLDING: How to Mold Living Hinges With No Flexing Required

Here are the five critical, intertwined components that must be perfected for a living hinge that doesn’t need to be flexed upon ejection.

Read MoreINJECTION MOLDING: Purging: A to Z

Use these steps as a guide to minimize the time and money it takes to switch materials and color on your presses.

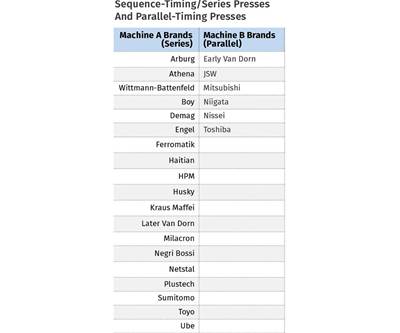

Read MoreINJECTION MOLDING: How Different Machine Types Handle Fill and Pack/Hold Times

The procedures are different between series and parallel machines. What type do you have? How can you tell? Here’s what you need to know.

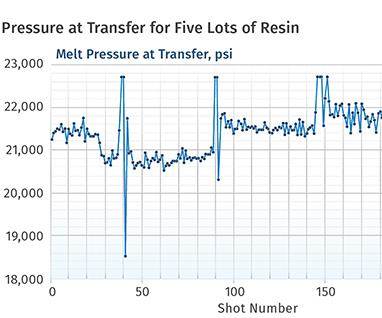

Read MoreINJECTION MOLDING: Processing Nylon…and Other Problems

As moisture content in this and other hygroscopic resins varies, so will your viscosity and process. Here’s how to deal with these issues

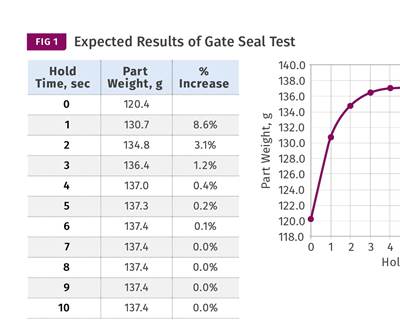

Read MoreINJECTION MOLDING: Gate Freeze Study: Danger in a Name?

The test actually determines the hold time needed to mold repeatable parts, and it should be done regardless of whether the gate freezes or not.

Read MoreINJECTION MOLDING: Properly Placing & Cooling Insulator Plates

Thermal-energy management from the mold to the platens is critical for making consistent parts.

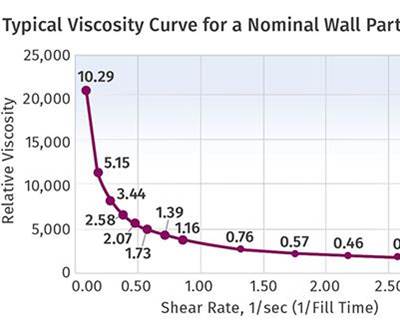

Read MoreINJECTION MOLDING: Do You Need to Profile Injection Velocity?

Look at the parts. If the answer is yes, the on-machine viscosity curve can help.

Read More