scientific molding

Why Multi-Cavity Molds Fill Unevenly

Balanced filling is critical for making identical parts, achieving high CPKs, holding tight tolerances, and getting “good” data from design of experiments.

Read MoreWhat Percentage of Barrel Capacity Should Your Shot Size Be?

The answer combines both experience and science, and it may be one of those molding details that gets overlooked but could be stealing a chunk of your profits.

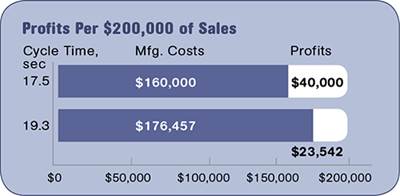

Read MorePlasticating Rates: Your Profits Are at Stake

To get the best cycle time you need the right machine, and few molders take the time to specify this critical component of the process.

Read MoreShort Shots Redux

Deliberately making a short shot permits you to do a scientific molding viscosity curve. It will also prevent you from damaging the mold by overpacking if you set shot size incorrectly.

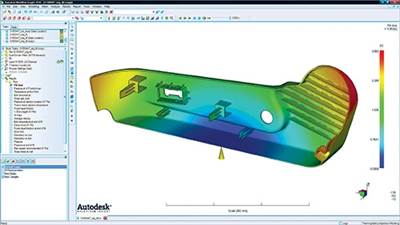

Read MoreMold Filling Simulation: What, When, Why, How

Mold-filling analysis is the right direction to go, but if you want to arrive at your destination—good parts and an efficient process—you’ll need to pay attention to all the details and select an experienced professional to do the analysis.

Read MoreScrews and Pellets: One Size Does Not Fit All

Screw design, pellet type/size and material behavior are all critical issues to consider to deliver uniform melt to the mold.

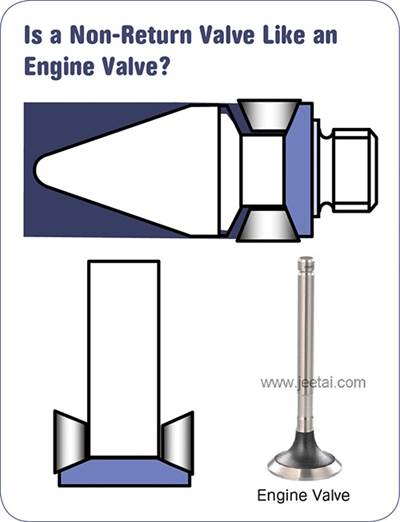

Read MoreWhy Non-Return Valves Leak

We all recognize that the non-return valve is a problem. The question is where is the research to figure out how to correct this so we have a better shot at making more consistent parts

Read MorePay Attention to Your Nozzle Body & Tip

These are overlooked components that can cost you thousands.

Read MoreInjection Molding: How to Set Second-Stage (Pack & Hold) Pressure

Most molders work with two parameters for establishing second-stage pressure. But within Scientific Molding there are actually four.

Read More