scientific molding

Injection Molding: How Repeatable is Repeatability?

Process repeatability is not a constant, but varies over time in response to a number of variables. That variation is not captured by a snapshot in time—measuring a discrete sample of parts. And the only way to manage that variation is with process controls that adjust each and every cycle.

Read MoreInjection Molding: Time for Another Look at Non-Return Valves

First and foremost, they must seal properly, and check valves with stepped angles or radiused seats perform the best.

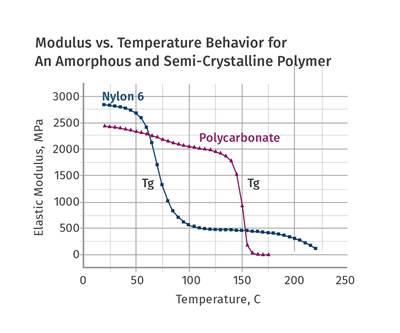

Read MoreMaterials: Cycle Time: Science vs. Rules of Thumb—Part 2

Understanding cooling—how a given material develops modulus as it solidifies—requires access to data that provides some insight into the relationship between modulus and temperature. Dynamic mechanical analysis is a helpful tool.

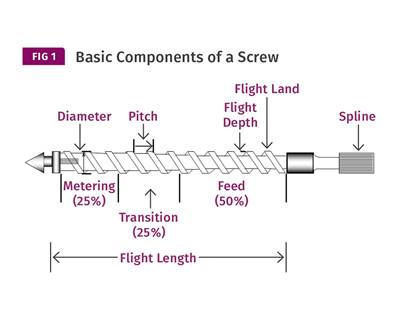

Read MoreInjection Molding: Are You Using More Than 65% Of Your Barrel Capacity?

If you are, you are inviting Murphy—as in trouble—to the party.

Read MoreClamp Tonnage: More Is Better...Right?

Determining the correct tonnage provides a foundation that must be rock-solid to avoid flash and damage. But applying excessive force can create problems with the part, mold, and machine.

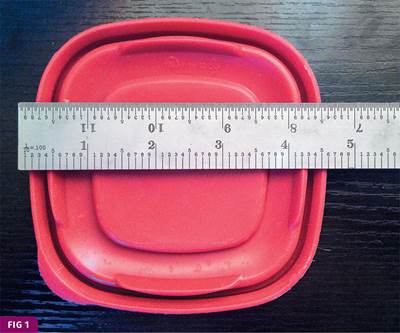

Read MoreCycle Time: Science vs. Rules of Thumb, Part 1

What temperature must the polymer reach so the part can be ejected from the mold? Here, more than for any other variable, ‘rules of thumb’ unfortunately prevail.

Read MoreBlock Cavities and Keep Molding

It goes against conventional wisdom, but molding with blocked cavities can be done while maintaining quality with the help of appropriate in-cavity sensors and process-control software.

Read MoreHow to Duplicate a Process From Press to Press

To adopt the right approach you must distinguish between machine and plastic parameters.

Read MoreUse Molding Simulation To Avoid Surface-Finish Defects

It’s not just for successful mold filling and cooling. Simulation can help predict and overcome cosmetic defects in molded parts.

Read MoreHow to Pick, Remove, and Replace a Nozzle Tip

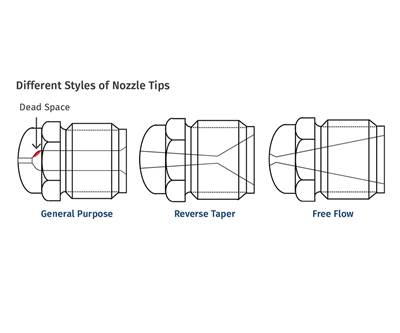

This small component can cause big problems. Here’s my procedure for picking and replacing yours.

Read More