Injection Molding

TOOLING AT NPE: Hot Runners & Coinjection Grab Spotlight

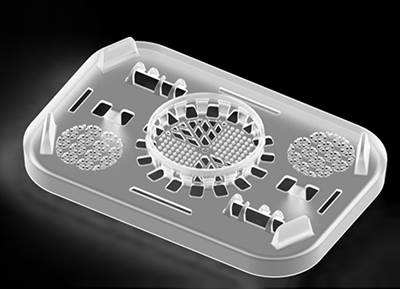

Tooling innovations at NPE focused primarily on multi-cavity closure and medical applications, though there was also a substantial emphasis on large automotive and appliance parts.

Read MoreThis Molder Wants Only the Tough Jobs

Need someone to injection mold fluoropolymers, highly filled PEE K, Torlon, or Ultem in complex shapes, tight tolerances, multiple cavities, and high volumes? “We love doing this,” says Tom Mendel, president of Performance Plastics Ltd. (PPL) in Cincinnati. “We’re not for everybody.

Read MoreRogan Corp. Is an Old Hand At Exploring New Frontiers in Plastics

the 78-year history of the Rogan Corp. is full of twists and turns. But one consistent theme stands out—an adventurous and inventive spirit that has put Rogan on the leading edge of a number of important trends in plastics—and even on the frontiers of space exploration.

Read MoreBrand-New Test Method Relates Material, Mold & Machine

It's the first material characterization method developed specifically for evaluating the injection moldability of a plastic melt.

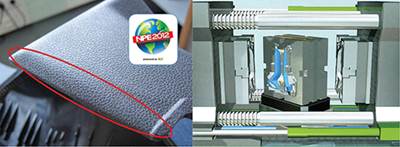

Read MoreFirst Commercial Use of ‘Dolphin’ Molding Process

italian molder deploys multi-component, hard/soft molding technology developed by Engel.

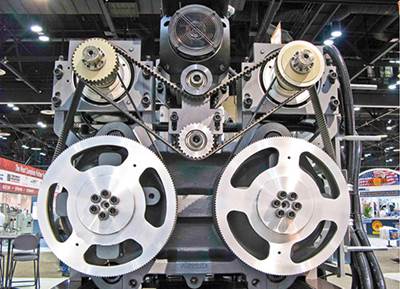

Read MoreNPE: New Machines Exhibit Sophisticated Molding Demos

More speed, more power, more precision, and more automated functions accomplished in and out of the mold. That’s exactly what injection machinery suppliers were offering at NPE2012.

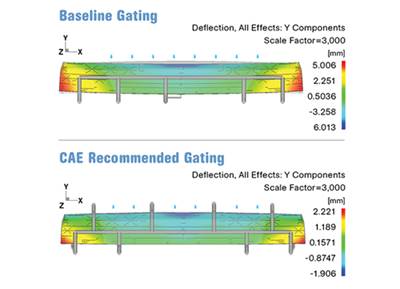

Read MoreTier 1 Automotive Molder Uses Team Approach to Mold Simulation

SRG Global calls in outside assistance to solve a tricky technical problem.

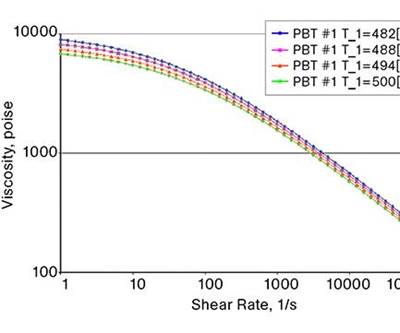

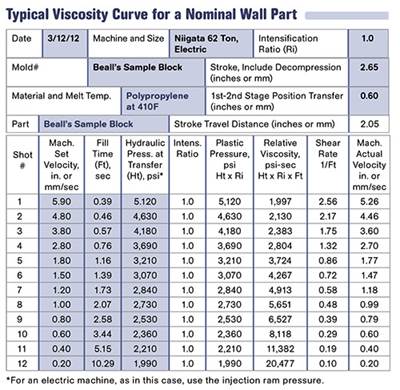

Read MoreUnderstanding Polymer Flow: Interpreting the Viscosity Curve

Take the time to do the viscosity curve on new molds. You will learn more in that hour than many learn in years about the process for this tool.

Read MoreNew Way to Characterize Moldability Of Resins & Part/Tool Designs

Experienced injection molders have long known that a resin’s melt flow index (MFI), measured under very low-shear conditions, provides very little information about how it will process under many orders of magnitude higher shear in an actual mold.

Read MoreAchieve Process Transparency with In-Mold Cavity Sensors

In plastic injection molding, the primary objective is to manufacture dimensionally and structurally consistent parts, independent of the molding machine being used.

Read More