Injection Molding

Top 10 Reasons Why Molders Fail At Implementing ‘Scientific Molding

What is Scientific Molding? And why do molders seem to have such a difficult time embracing its concepts? Here are some thoughts on the matter.

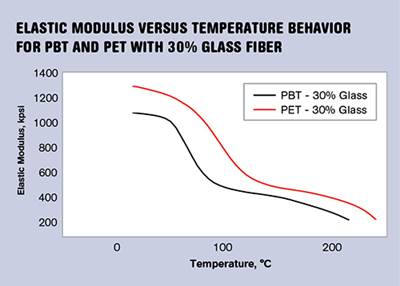

Read MorePBT & PET Polyester: Part 2 The Performance Factor

All things being equal, PET will outperform PBT mechanically and thermally. But the processor must dry the material properly and must understand the importance of mold temperature in achieving a degree of crystallinity that allows the natural advantages of the polymer to be realized.

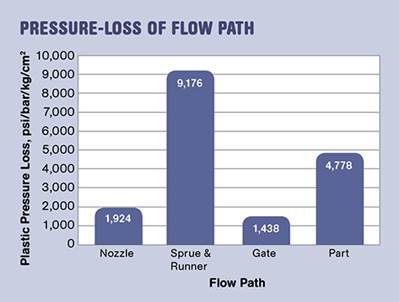

Read MoreGet the Most From Your Tooling

The history and culture of the molding industry has been to pull out every trick possible to work around design, resin, tooling, processing, and testing issues once the mold arrives. It is time to rewrite history.

Read MoreNovel Materials Stretch Process Capabilities

The potential for new or unusual materials to broaden the application potential of standard plastics processes was explored in a number of papers at April’s SPE ANTEC conference in Orlando, Fla.

Read MoreMolder Takes 3D Printing In-House to Speed Product Development

“Bringing this function in-house is very much in keeping with the way our company conducts its 大象传媒.

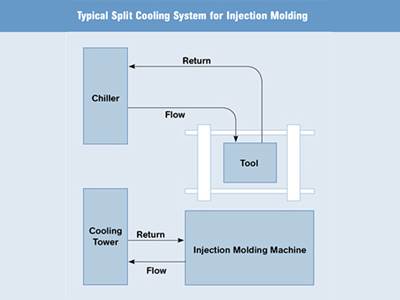

Read MoreEnergy Miser: For Energy-Efficient Water Cooling, Raise Temperatures to Cut Demand

Many plants use chilled-water temperatures that are far lower than are actually needed by the process. This has a direct effect on the cost of chilled water.

Read MoreNew Machines & Processes for Medical, Auto, Packaging, Electronics

Engel’s technical symposium in June attracted 2700 visitors from 35 countries to two days of technical presentations and 18 injection molding exhibits at the company’s plant in St.

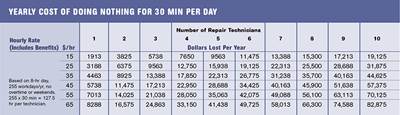

Read MoreEstablish a True ‘24/7’ Production Process

New or existing mold trials need to produce a production-worthy process that will run 24/7.

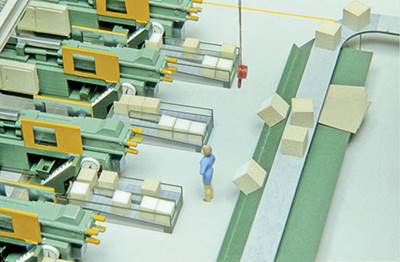

Read MoreUnderstanding Automation for Pipette Molding

While simple looking enough, the pipette can be challenging to process. They generally have to be produced in high volumes without sacrificing quality due to their demanding applications. Automation is key to making this happen.

Read More