Injection Molding

Liquid Infusion of UV Stabilizer

Process involves dipping the parts in an aqueous bath for a short period

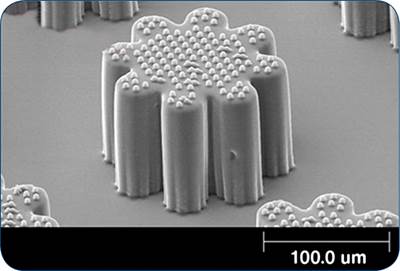

Read MoreSecrets of Success in Micro Molding

Medical-device, electronics, and biopharmaceutical manufacturers need new micro-molded products to create tinier, less invasive, and/or space-saving micro devices.

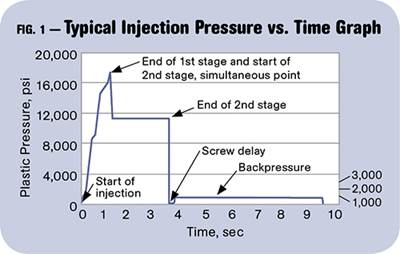

Read MoreImprove Profits by Graphing Injection Pressure

Graphing is a powerful aid in optimizing the process and troubleshooting both process and machine issues.

Read MoreNow You Can Measure Pellet Moisture In the Hopper, in Real Time

Take the guesswork out of drying with new technology.

Read MoreTightening the Screws on Precision Molding Of Thermoplastics & LSR

Fairly consistent focus of annual conference was how to get better control of the molding process.

Read MoreMaking Older Hydraulic Injection Machines More Energy Efficient

Processor Strategies: Motor Controllers

Read MoreFive Cases Where Microcellular Foaming Paid Off

The MuCell process for producing microcellular injection molded parts is used and accepted globally as a technology option for providing a more dimensionally stable part through a reduction in residual stress, along with increased productivity versus solid injection molded parts.

Read MoreGet Better at Multi-Material Molding

Since each multi-material application is unique, there’s no standard best method for success. Each molding solution must be tailored to meet the needs of the final product.

Read MoreWhat to Calibrate on Your Press

There are different approaches to meeting the goal of making parts identically. At the heart of all them is the process or the machine setup sheet. My bet would be you cannot find two that are identical.

Read More