Injection Molding

Troubleshooting Mold Temperature Control

Mold-temperature control is just one of many process elements that can affect the quality of an injection molded part.

Read MoreMolders Go ‘Rapid’ for Prototyping and Manufacturing

Three forward-thinking custom molders have taken steps to streamline their manufacturing, expand new product development, and add to their customer base—and all in a more cost-effective manner than ever before.

Read MoreMoldmaker Explores New LSR Molding Technologies

Can liquid silicone rubber (LSR ) be overmolded onto polypropylene?

Read MoreNew Drying Technology Helps Moldmaker Get Back to Molding

System solves quality problem that had hamstrung previous molder.

Read MoreReifenhauser Buys Westland, Enters U.S. Screw & Barrel Market

In a move to give its Reiloy Metall screws and barrels operation a stronger position in North America, Reifenhauser of Troisdorf, Germany, has purchased Westland Corp., Wichita, Kans.

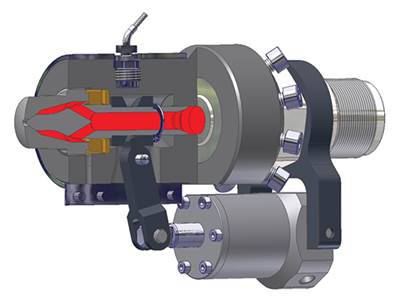

Read MoreLiquid CO2 Spot Cooling Gets Into Tight Spots in Molds

Cooling of long, thin cores, fillets, slides, ejectors, or other hard-to-reach spots in injection molds can present difficult challenges.

Read More‘Expansion Molding’: New Method For LSR Micro-Molding

X-melt or expansion molding technology was originally developed by Engel to fill thin-wall parts that require extremely fast injection.

Read MoreMore Effective Mold Maintenance: It’s All About the Data

When tooling issues are shutting down presses daily and you can’t muster the mold maintenance and operating records to figure out why, then like the song says, “Who ya gonna call?” The answer to that question proved crucial to Cosmetic Specialties International (CSI), LLC in Oxnard, Calif.

Read MoreMinimize Screw Recovery & Cycle Times

There are hundreds of details you must identify and control to run a successful molding plant. One that is almost always at the top of the list is optimizing cycle time. Shorter cycles that make acceptable parts improve profits.

Read More