Extrusion

Belling Machine Forms 'Rieber' Socket in PVC-O Pipe

Italy’s SICA has developed an innovative Rieber belling process specific for PVC-O pipes. At the same operating pressure, these pipes require a wall thickness of about 35-40% less than those in conventional PVC pipe and allow the construction of water supply pipes up to 25 bar of operating pressure.

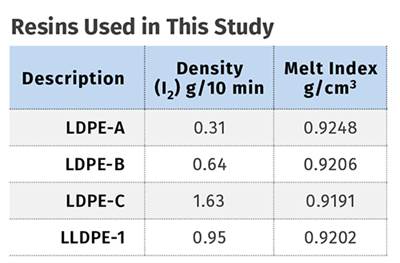

Read MoreFormulating LLDPE/LDPE Blends For Abuse–Resistant Blown Film

A new study shows how the type and amount of LDPE in blends with LLDPE affect the processing and strength/toughness properties of blown film. Data are shown for both LDPE-rich and LLDPE-rich blends.

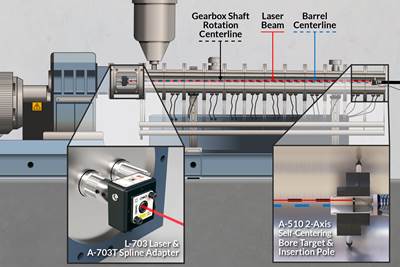

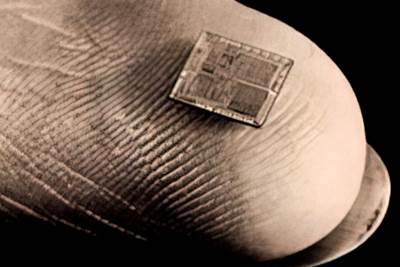

Read MoreLaser Helps Keep Twin-Screws Aligned

Small laser helps processors align twin-screws more efficiently.

Read MoreInlet Trap Keeps Volatiles Out of Extruders

High-capacity vacuum pump inlet trap that protects extrusion lines and vacuum pumps from the volatiles.

Read MoreExtruding PCR? Consider a Vented Extruder

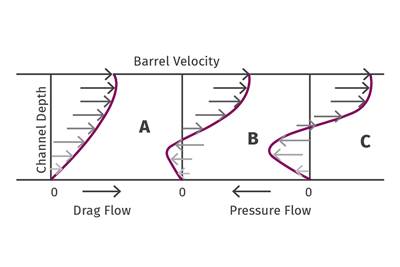

You’ll need two-stage screws to extract volatiles that post-consumer reclaim will likely contain. Screw design can be a complex balancing act. Here’s what you need to know.

Read MoreStill Time to Register for SPE Extrusion TopCon

‘Precision Extrusion’ Topcon will be held June 21-23 in Nashville.

Read MorePregis Performance Flexibles: In the ‘Wow’ Business

Pregis went big and bold with investment in a brand-new, state-of-the-art plant and spent big on expanding an existing facility. High-tech lines, well-known leadership and a commitment to sustainability are bringing the “wow” factor to blown film.

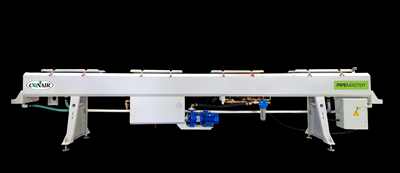

Read MoreTank Offers High-Capacity Cooling for Pipe

Suited for extruded PVC and polyolefin plastic pipe up to 24.9 in. in size.

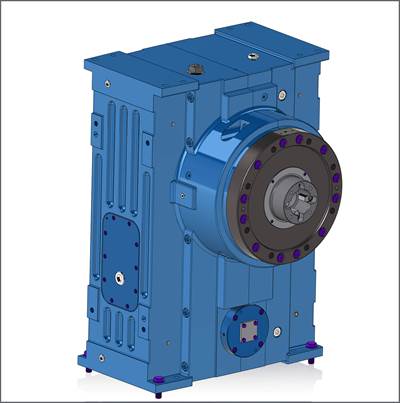

Read MoreNext-Generation Gear Reducer is Sleek, Robust

Can accommodate a variety of extrusion requirements, including those with high and low torque, speeds and extrusion pressures.

Read More50 Years of Headlines … Almost

I was lucky to get an early look at many of the past half-century’s exciting developments in plastics. Here’s a selection.

Read More