Extrusion

Colines Expands Reach in Stretch Film

Italian supplier of stretch film lines buys NO.EL Industrial Automation, which focuses on specialty systems for winding and stretching extruded film.

Read MoreYoung Stretch-Film Processor Bets on Nanolayers

Going up against companies with as much as double its capacity, young stretch-film processor Zummit believes that new technology — notably 59-nanolayer films — will give it a competitive edge.

Read MoreProfile Processor Pexco Expands in Fluoropolymers

Purchases Enflo, well-known for providing customers with PTFE products in a range of markets.

Read MoreSystem Takes Aim at Food-Packaging Applications

Gneuss will present new recycling system at the K Show this October.

Read MoreADS Planning $65 Million Expansion at Ohio HQ

ADS Engineering & Technology Center to add jobs, and expand state-of-the-art capabilities in materials science, manufacturing technologies and stormwater and onsite septic wastewater management solutions.

Read MoreDeDuster Systems Cleans Up rPET Sheet

rPlanet cut its gel count drastically—allowing it to sell more sheet at prime prices—after installing a DeDuster system.

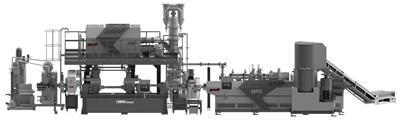

Read MoreIntegrated Recycling Lines Sort, De-label, and Wash

Amut will present recycling and extrusion technologies at K Show 2022

Read MoreWhat Are You Risking With Outdated Controls?

Though introduced about 50 years ago, many extruders in operation today are still running without PLCs. What’s at risk? Increased downtime and scrap, machine damage and, more importantly, risks to the health and welfare of employees.

Read MoreVariable-Diameter Air Ring Cools Film Above Frost Line

Tower-mounted adjustable ring adds cooling so that blown film can run at optimum line speeds with structures having soft inner skin layers that tend to block.

Read MoreCrosslinking Process Promises Thinner, Higher-Performance PE Films

Technology combines UV curing system with photo initiator promoter masterbatch.

Read More