Young Stretch-Film Processor Bets on Nanolayers

Going up against companies with as much as double its capacity, young stretch-film processor Zummit believes that new technology — notably 59-nanolayer films — will give it a competitive edge.

A relatively young extrusion processor is in the embarking on an aggressive investment plan in an effort to establish itself as a different kind of company in the cast stretch-film ´óĎó´«Ă˝. , which has three 5-layer lines, one 7-layer line and a 9-layer line running at plants in Phoenix, Ariz., and Columbus, Ga., will soon fire-up a 59-nanolayer cast-stretch line in Georgia from Italian machine builder Colines equipped with a die/feedblock package from Cloeren Incorporated.

Research conducted in 2019-2020 by market-research firm Mastio & Co. pegged stretch film as a 2.4 billion lb/yr market in North America. The five biggest stretch-film processors — identified by Mastio as AmTopp, Berry, Malpack, Paragon and Sigma — accounted for more than 80% of that capacity. So, when Zummit opened in Phoenix in 2016 and expanded into Georgia amid the global pandemic in 2021, its strategy was to focus on being a different kind of stretch-film producer, notes Miguel Peredo, CEO. In boxing parlance, Zummit knew it had to punch above its weight. When the new line is up and running, Peredo estimates Zummit will have about 200 million lb of annual capacity, about half of what each of the big five can bring to the market.

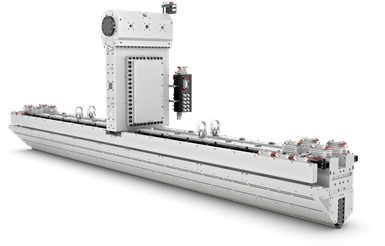

Zummit Plastics latest cast-stretch line from Colines will be a six-up, nanolayer system capable of running at rates up to 3900 lb/hr. (Photo: Colines)

“When we created this company the idea was to be different,” says Peredo, who has been in the stretch-film ´óĎó´«Ă˝ for more than 25 years. “For us, it’s not all about pounds. It’s about technology, service and sustainability.”

Nanolayer technology for cast stretch broke through in Europe as a result of collaboration between Eddy Hilbrink, who headed up R&D for Dutch processor Apeldoorn Flexible Packaging B.V. (now Trioworld) and Cloeren President Peter Cloeren. In 2008, Apeldoorn installed a 27-nanolayer line. When Plastics Technology caught up with Hilbrink at NPE2015, he said his company was in the process of converting a line to 55-nanolayers.

A feedblock and die package from Cloeren enables Zummit to produce stretch film at an industry-high 59 layers. (Photo: Cloeren Incorporated)

In North America, if stretch-film processors are running nanolayer structures, they aren’t saying much about it. Peredo says there is nanolayer capacity on the market — for perhaps up to 42 layers — but believes the 59-nanolayer line at Zummit is the record holder so far in North America. The ability to tailor film structures and recipes across 59 layers not only boosts film performance but offers the opportunity to downgauge as well. Says Peredo, “For example, if a customer is using 0.8-mil-thick film, I can come in at maybe 0.68 mil. They're going to have same performance with the thinner film but significant savings in material.”

Downgauging is not the only path Zummit has taken toward making its products more sustainable. The company also produces a product call BIO-Zummit, which is made with an undisclosed additive that promotes biodegradability. In laboratory tests, biodegradation reached more than 60% in 607 days in a simulated soil environment. “Being environmentally conscious is part of our culture,” says Peredo, who notes that employees wear green-logoed shirts and the firm has green silos to illustrate its commitment to sustainability.

Photo: Zummit Plastics

The line Zummit will be installing this quarter is the third it has purchased from Colines. All are AllRollex 3000-mm (120-in.) six-up lines. Two are in Columbus. The seven-extruder lines can process at up to 3900 lb/hr. Zummit also has stretch lines from Davis-Standard and SML. Combining the Phoenix and Columbus facilities, Zummit has more than 200,000 ft2 of manufacturing space and employs about 180.

Related Content

US Merchants Makes its Mark in Injection Molding

In less than a decade in injection molding, US Merchants has acquired hundreds of machines spread across facilities in California, Texas, Virginia and Arizona, with even more growth coming.

Read MoreFirst Water Bottles With Ultrathin Glass Coating

Long used for sensitive juices and carbonated soft drinks, KHS Freshsafe PET Plasmax vapor-deposited glass coating is now providing freshness and flavor protection for PET mineral water bottles.

Read MoreWhat to Look for in High-Speed Automation for Pipette Production

Automation is a must-have for molders of pipettes. Make sure your supplier provides assurances of throughput and output, manpower utilization, floor space consumption and payback period.

Read MoreMedical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Extrusion simulations can be useful in anticipating issues and running “what-if” scenarios to size extruders and design dies for extrusion projects. It should be used at early stages of any project to avoid trial and error and remaking tooling.

Read MoreRead Next

What You Need to Know to Make World-Class Stretch Film

Advances in materials, feedblock/die technologies, and winding can help processors develop more sophisticated cast-stretch products.

Read MoreFor PLASTICS' CEO Seaholm, NPE to Shine Light on Sustainability Successes

With advocacy, communication and sustainability as three main pillars, Seaholm leads a trade association to NPE that ‘is more active today than we have ever been.’

Read MoreLead the Conversation, Change the Conversation

Coverage of single-use plastics can be both misleading and demoralizing. Here are 10 tips for changing the perception of the plastics industry at your company and in your community.

Read More