Tank Offers High-Capacity Cooling for Pipe

Suited for extruded PVC and polyolefin plastic pipe up to 24.9 in. in size.

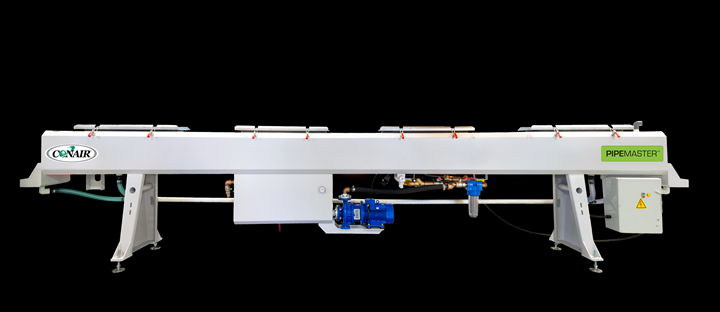

Conair’s new PipeMaster MSBH Series Spray Cooling Tank provides a compact, high-efficiency water-spray cooling solution for extruded PVC and polyolefin plastic pipe up to 24.9 in. in size. Typically positioned after the vacuum tank, the MSBH tank accepts the extrudate onto rollers and carries it under a series of water spray nozzles that rapidly complete the cooling process and bring the pipe or profile down to finished size.

Available in tank lengths from 13 to 19.7 ft depending on application requirements, MSBH Series cooling tanks are engineered to deliver a controlled, high-intensity spray of cooling water droplets to the hot extrudate surface. These droplets capture heat from the extrudate surface and conduct it away through the process of evaporation. Compared to full-immersion cooling tanks of similar cooling capacity, evaporative spray cooling tanks like the MHBH Series are about 20% more efficient in heat transfer. Thus, they can provide maximum cooling capacity while using the minimum of valuable floor space.

Photo: Conair

MSBH spray-cooling tanks feature rugged stainless steel tank construction, painted steel frame supports, frame-mounted controls, and wide, height-adjustable bases for stability and safety. Inside, the tanks are equipped with size-adjustable rollers and high-intensity spray nozzles to facilitate rapid product size changes while maintaining consistent cooling spray patterns and pressures. All tank internal/wetted surfaces are constructed with 304 stainless steel for long-term corrosion resistance.

Water-recirculating systems include a sturdy industrial pump and pressure gage, and are built with common plumbing components that make maintenance or repairs easy and inexpensive. The tanks can be configured to receive recirculating water via direct injection from the customer’s central water system, or equipped with heat exchangers that can be served by pressurized chiller loop systems.

Related Content

-

How To Identify Resin Degradation in Single-Screw Extruders

Degradation can occur in many single-screw extrusion operations, and typically occurs due to minor design flaws in the screw. Here is how to track it down.

-

What to Know About Your Materials When Choosing a Feeder

Feeder performance is crucial to operating extrusion and compounding lines. And consistent, reliable feeding depends in large part on selecting a feeder compatible with the materials and additives you intend to process. Follow these tips to analyze your feeder requirements.

-

Part 2 Medical Tubing: Use Simulation to Troubleshoot, Optimize Processing & Dies

Simulation can determine whether a die has regions of low shear rate and shear stress on the metal surface where the polymer would ultimately degrade, and can help processors design dies better suited for their projects.