Extrusion

Physically Foamed HIPS Is New Factor in Rigid Packaging

Relief for escalating costs of packaging materials and an opportunity to address sustainability goals are two factors that have helped attract global attention to a new physical foaming technology for HIPS packaging.

Read MoreTo Troubleshoot Profile Extrusion, First Get to Know All the Variables

It requires patience, logical thinking, and a methodical approach to assess each unique problem and solve the problem in a timely fashion.

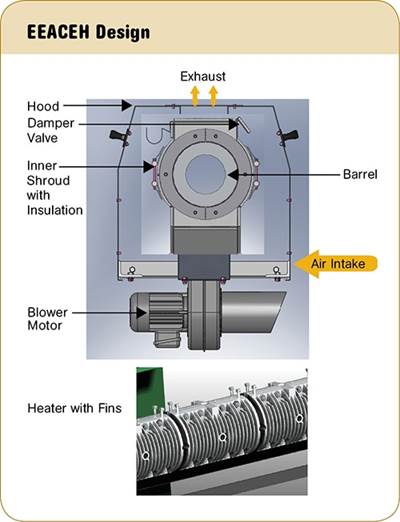

Read MoreNew Barrel Heater/Cooler Saves ‘Juice' to Run an Extruder

New, patent-pending design is said to reduce both radiant and convection heat losses.

Read MoreWhere Does Shear Heating Occur? Here’s How to Find Out

One of the least understood yet most important concepts is viscous dissipation, which is the shearing or stretching of the polymer between the rotating screw and stationary barrel, causing heat to develop in the material.

Read More'Green'...And Microwaveable Too

New technology from Teknor Apex Co., Pawtucket, R.I., eliminates a property tradeoff that could allow polylactic acid (PLA) to supplant polystyrene and polypropylene for microwavable frozen-food trays, lids for hot beverage cups, and carry-out containers.

Read MoreReport Details Opportunities for Battery-Film Processors

If you make battery separator films you might be interested in a report released recently by Eldib Engineering & Research, Berkeley Heights, N.J.

Read MoreDuPont Honors Packaging Innovators

Sixteen winners honored in 23rd annual awards ceremony.

Read MoreWood on Plastics: Dramatic Shifts and Opportunities in Electronics

Reshoring is a possibility as manufacturing of components will increasingly be conducted closer to market.

Read MoreDetermining the Maximum Machine Direction Orientation (MDO) Possible for Sheet

Given a set film thickness, width and material, how to you determine how much machine-direction orientation (MDO) is possible for a sheet.

Read More