Extrusion

Energy Savings Pay Off Fast for Custom Profile Processor

More and more processors are looking an energy as a place to cut costs and improve their competitive position.

Read MoreSmart Line Control Works with Smart Phones

Recent upgrades have equipped Davis-Standard's EPIC III extrusion supervisory control system with extensive remote-access capabilities, allowing multiple lines to be monitored via a computer or cell phone from any location.

Read MoreExtrusion: A Roll Is a Roll Is a Roll?

Chill rolls may looks simple and shiny, but they play a critical part in cooling and polishing film and sheet and are not all the same.

Read MoreProcessor Strategies - Cadillac Products Packaging Move to Nine Layers Means Better Bags, High-Value Niches

The story of Cadillac Products Packaging is a 65-year-old tale that combines a steadfast commitment to innovation and customer satisfaction with a broad range of product offerings.

Read MoreTips and Techniques: How to Downgauge Film Without Losing the ‘Feel’ of Quality

These days, blown film processors supplying converters and packagers with high-end materials are between a rock and a hard place.

Read MoreOn-Site: Well, Well, Well... Processor Taps into Novel Underground Cooling Solution

In 2008, Olle Mannertorp and his co-owners of Multifilm Packaging (multifilm.com) had a decision to make.

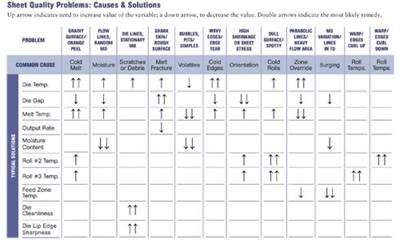

Read MoreFollow This Action Plan to Keep Your Sheet Dies in Line

Getting back into production after maintenance or troubleshooting requires a coordinated effort. Here’s how to get your sheet line up and running as fast as possible.

Read MoreProcessor Strategies - Royal Group Profile Maker Gives Environment The ‘Royal’ Treatment

When you’re already a leader in your industry, you might be tempted to simply stay the course and not worry about issues such as sustainability and carbon footprint.

Read MoreExtrusion: Why Is Material Backing Up Into the Feed Throat?

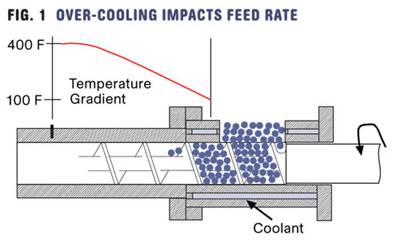

Could starve feeding be the cause of material not moving through the feed section and backing up into the feed throat of an extruder?

Read More